Are My New Batteries Really New?

In a recent post on thermal runaway, I gave the advice of always using “well matched” batteries. One way to do this is to use new batteries, then continue to use these batteries as a set. But this assumes the the batteries are well matched to begin with — i.e. have the same charge when they are new. This seems like it should be a safe bet, but there are been reports on this blog and elsewhere on the internet of new batteries that don’t perform well. This post explores the issue for a trail camera favorite: Lithium Iron Disulfide L91 (Energizer (R) Ultimate Lithium (TM) AA) batteries, and gives several independent ways for determining whether they are likely fully charged when new, or not. These methods range from measuring the voltage of each battery, to visually examining the battery labels. In an update to the original version of this post, I also consider the possibility of counterfeits — lower cost alkaline cells packaged as premium Lithium batteries.

Measuring the Battery Voltage

All AA batteries are rated nominally at 1.5 Volts — a measure of the battery’s potential to drive current through a circuit against some resistance. But like most batteries, the actual voltage of a Lithium Iron Disulfide (LiFeS2) battery varies with use and with the available charge.

The easiest measurement to make is of the “Open Circuit Voltage” (OCV) of the cell. The term “Open Circuit” just means without any current flowing. This can be done with a Volt meter by pressing the leads against the positive and negative terminals of the battery, as in the photo above.

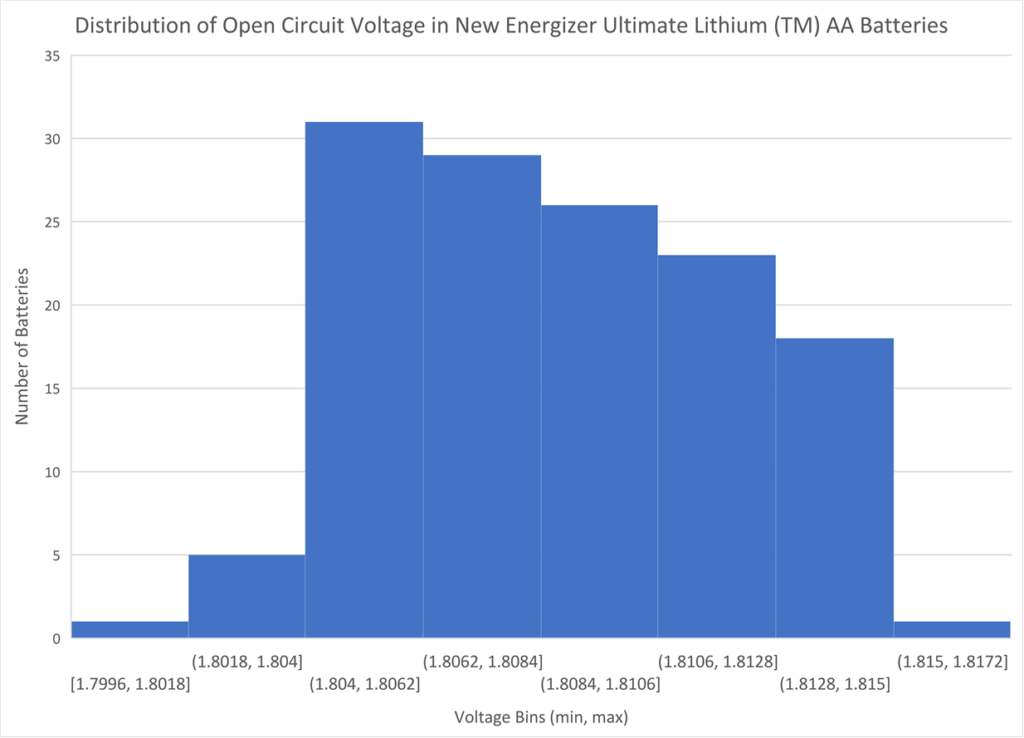

According to the Energizer (R) Ultimate Lithium (TM) specification, the OCV of fresh batteries range from 1.79 to 1.83 Volts. A battery with OCV below 1.79 Volts is likely partially discharged. A battery with an OCV above 1.83 Volts is likely counterfeit. Below is a histogram of the OCV for a set of 134 new batteries I measured recently, showing that almost all of the distribution occurs between 1.800 and 1.815 Volts.

Note the small size of this range: only 0.04 Volts between 1.79 and 1.83 Volts. A high quality digital voltage meter or battery tester is best for making this fairly precise measurement.

How Reliable is voltage as an Indicator of a New Battery?

Unfortunately, the a measurement of OCV is not a perfect indicator of the newness of a battery and is not strictly “necessary” or “sufficient”:

- Necessary: It is very likely that a new battery will have a voltage in the range of 1.79 to 1.83 Volts. The histogram above shows the populations of 134 new batteries within different voltage bins. The distribution drops off sharply above 1.815 Volts, and and there are zero batteries below 1.7996 Volts. Having said this, I have measured one new battery with an OCV at ~1.7 Volts. A subsequent controlled discharge showed that the battery, none-the-less, exceeded the manufacturer’s specification for capacity. So this condition is necessary, likely greater than 99% of the time.

- Sufficient: Just because the voltage on a LiFeS2 battery exceeds 1.79 Volts does not guarantee it is new. I have measured discharges of multiple batteries whose initial OCV are greater than 1.79 Volts but whose capacity was significantly less than than the full charge of the battery. These batteries have all been “slightly used” — i.e. not directly out of the package. A battery directly out of the package with an OCV greater than 1.79 Volts is likely new, but a battery taken from a trail camera with an OCV greater than 1.79 Volts may be significantly discharged.

Examining the Batteries Themselves

Careful visual examination of the batteries themselves can also help determine whether the batteries are likely new, or not.

Avoid “Too Good to be True”

In reviews online, there are reports of people receiving “too good to be true” pricing from online vendors of little reputation, in non-standard packages (e.g. zip-locked bags). These would all seem to be pretty strong suggestions that the batteries are not direct from the factory and therefore may not meet manufacturer specifications.

Check for Consistency in the Battery Labels

The labels themselves contain additional information. By checking whether all the batteries in a typical package of 8 or 12 batteries have the same label information, one can determine whether they were likely packaged in the factory, or not.

- The format of the printing and logo on the label: I’ve seen examples of two label designs — one for cells made before 2019 (top battery in photo above), and one for those made after (bottom battery in photo).

- An “Expiration Date”: Also called “shelf life date” — e.g. “12-2038” and “12-2039” in the photo above. The manufacturer warrants that batteries used before this date will provide greater than 95% of their rated capacity. In batteries I have seen with dates after 12-2039, this field appears in the middle of the battery; in batteries with dates of 12-2038 or earlier, this field appears around the top (positive) side of the battery. I have never seen a battery with a shelf life whose month different than “12”.

- A Manufacture Date: The manufacture date is given as a four digit laser-scribed number near the negative terminal of the battery. The format is MMYY, thus “1115” would be (November) 11, (20)15. The difference between the manufacture date indicated on the battery and the shelf life date is about 20 years — consistent with the long shelf life advertised for the battery.

If batteries from the same package have different logos, or different shelf-life dates, they were not manufactured together. More subtly, if the batteries in a package have a different manufacturing date inscription, or if some are missing the date inscription, they were also not manufactured together. Any of these discrepancies would indicate that batteries made at different times have been repackaged — clearly a cause for concern.

Checking for Old Batteries in New Packages

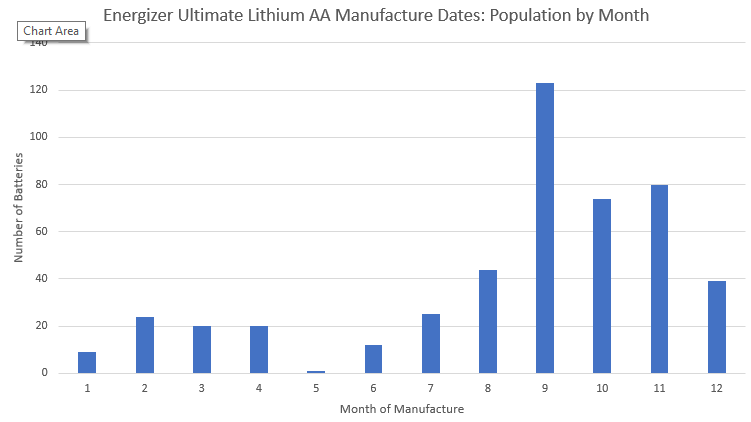

Curious about the ability of the manufacturer to avoid “stockpiling,” or long warehousing times of batteries in the supply chain, I tabulated the date codes from nearly 500 batteries that were sitting in our “to be recycled” box. This collection bears manufacture dates as early as April, 2012, and as late as December, 2017. Below I have plotted a histogram of the number of batteries in this collection by the month they were manufactured.

This data suggest the the production of these batteries is uneven, with a peak in September and high around the end of the year, and a minimum early in the year to early summer, reflecting changes production to meet seasonal demand. This cycle is typical year over year, suggesting that production is well-matched to consumption, and that there is no need for any long-term (multi-year) “stockpiling” in the (legitimate) supply chain.

Thus, “new” batteries with old (> 2 year) manufacture dates indicate that the batteries have spent a longer than usual time in the supply chain, and may therefore indicate something amiss in their path to you.

Checking the Label for Evidence of Heat Damage

It is possible that exceeding this temperature range somewhere in the supply chain could reduce the storage capacity of the battery. The recommended temperature range for storage for LiFeS2 batteries is quite wide — from -40°C to 60°C (-40°F to 140°F). This is one of the properties that make them so attractive for trail camera power. Still, this range is limited.

Because the plastic label shrinks at high temperature, it can indicate whether the battery has been exposed to thermal stress. Thus, shrinking of the battery label, visible as a a tightening near the positive terminal, or as a separation of the seam along the length of the battery, would be causes for concern in “new,” still packaged batteries.

Sheep in Wolves’ Clothing

One way to counterfeit a premium battery is to put the wrapping and packaging for the more expensive battery on a lower cost cell. For example, putting Energizer (R) Ultimate Lithium (TM) packaging on an alkaline battery.

I would like to thank Phil Richardson, who wrote of his experience with just such a scenario in a comment to an earlier version of this post. Phil correctly pointed out that not only do LiFeS2 batteries have a higher open circuit voltage when new: ~1.8 V) vs. new alkaline cells (~1.6 V); but the Lithium cells are also much lighter — weighing just 15 grams per AA cell vs. 23 grams for the lower performance alkaline cells. You can make this measurement with a small scale, but the difference is large enough that it can be felt directly if you have a reference object, e.g. a known LiFeS2 or alkaline battery, to compare with.

One other tell tale is that the Energizer (R) Ultimate Lithium (TM) batteries have an indented ring at the top of the cell, which one can feel with a fingernail beneath the plastic cover. Standard alkaline cells are one solid cylinder from bottom to top, with no indented ring. In the photo below, I’ve removed the covering at the top of an EUL cell, and an alkaline cells for comparison.

Summary

“New” Energizer (R) Ultimate Lithium (TM) batteries are likely to be true LiFeS2 batteries and fully charged if:

- They are in factory-standard packaging that has not been opened or tampered with

- They were purchased from a reputable vendor at a fair market price

- Their open circuit voltage is between 1.79 and 1.83 Volts (vs. 1.6 Volts for alkaline cells)

- They weigh approximately 15 grams (vs. 23 grams or more for different chemistry cells)

- They have and indented ring at the top of the cell which can be felt through the plastic cover with a fingernail

- All of the cells in a given package have the same label design, shelf-life date, and laser-scribed manufacture date code

- Manufacturer dates are within ~2 years of the time that you receive them “new”

- None of the cells in the package have labels which have been damaged by exposure to high temperatures, as indicated by shrinkage of the plastic label.

Have you had experience with new LiFeS2 batteries not meeting their charge specifications? Were any of the criteria above violated? Please let me know in comments section below.

Disclaimer

All data presented in this post is based on measurements I have made on batteries purchased from various vendors over the past 4-5 years in the US. I present this data “as is” , with no financial interest in, endorsement of, or prejudice towards Energizer (R) Ultimate Lithium (TM) batteries, or Energizer LLC, or any of its subsidiaries or partners.

I use rechargable AAs in almost all of my camera traps, the only exception being y Bushnells which will not run on rechargables due to the batteries’ low voltage of abut 1.34 when fully charged. All of my rechargables are kept in sets of six or eight depending on how many the camera requires; each set is dated by purchase date. I use Imedion, Energizer and Amazon rechargables which, until recently, were apparently make in the same factory in Japan (where some other brands are also apparently made. It’s much less expensive to use rechargables when possible and avoids the throw-away aspect of camera trapping.

There is a lot to be said for re-chargeable batteries, for sure, especially the modern NiMH chemistries that have all but replaced the environmentally challenged NiCad cells. I did want to be clear that we recycle, rather than “throw away” dead cells. That being said, they are only good for one charge cycle, whereas NiMH cells can be charged 100’s of times. Energizer gives a good summary of differences between the NiMH rechargeable cells and primary Lithium and Alkaline cells. See Table 1 in https://data.energizer.com/pdfs/nickelmetalhydride_appman.pdf . In this list, the performance at low temperature, longer self-discharge time, and higher capacity of the Lithium cells figure highly in our choice to use these in remote installations, with long service times, and spanning multiple seasons. The NiMH would be a great choice for installations closer to home, but in an effort to get all of the value we can out of the Lithium cells, we generally deploy the partially used batteries in local sets. This gives me (arguably too much) opportunity to understand them in detail. Sounds like you have had good experience with the NiMH cells — thanks for commenting.

load testing not recommended ?

Ron, I’m glad you asked! The short answer is that in addition to being hard to explain, “load testing”, or more generally, “measurements of internal resistance” don’t seem to give any better insight into the newness of a battery than the OCV for LiFeS2 batteries. As such, during one of the rigorous (some say brutal :)) editorial review sessions here at Winterberry Wildlife, it was dropped from this post.

The long answer is that:

– static, or DC, load based tests, where you compare the OCV to the voltage under some fixed load, reflects the behavior of a secondary electrochemical reaction in these cells, and not the primary (capacity-relevant) reaction. In the Energizer literature from the second reference (my emphasis): “A commonly used method whereby the resistance is calculated as shown below must not be used with AA size lithium iron disulfide batteries as the values are much higher than the real values. This is due to the initial OCV of AA size lithium iron disulfide batteries being higher than the OCV of the chemistry that actually controls the battery’s discharge performance.”

– a more subtle test, which requires specialized (but not very expensive) equipment instead makes a series of rapid (1000 per second) voltage measurements at two different loads to estimate the internal resistance of the cell. I actually made such measurements on the same collection of new batteries included in the OCV histogram in the blog post. The spread is larger — between 136 and 200 mOhms, and overlaps significantly with the distribution of cells that I know were significantly discharged. Thus, it gives little additional information over the OCV as far as “newness” goes.

Having said all this, I do think the internal impedance can be used to help estimate the “state of charge” of a LiFeS2 battery. The subject, I think, of a future post in the “battery series”.

I have been using AA and AAA Energiser Ultimate Lithium for 2 years. Mine always read 1.79v and weigh 15gms. They too have a manufacture date code with a 20 year shelf life. But I have just received another order from a different seller and these have the characteristics of an alkaline battery. Reading of 1.59v and weighing 23gms. No manufacture code. So I believe these to be counterfeit.

Very interesting — I had neglected to mention weight as an indicator of potential counterfeits — but it is! According to Energizer, AA LiFeS2 at 15 grams; Alkaline at 23 grams; NiMH at 30 grams. The combination of weight and open circuit voltage seem damning. It would appear that these batteries are garden variety alkaline cells. I assume these are “visually identical” to the other Energizer Ultimate Lithium’s you’ve used?

I updated this post based on your comment. See above for another tell tale for Lithium vs. Alkaline — an indented ring at the top of the cell which can be felt through plastic label with a fingernail. Are your (presumably alkaline) cells missing this ring, too?

Pingback:Building a DSLR Camera Trap: Part 1 - Design Elements - Winterberry Wildlife

Are you saying that, if I use my multimeter (OCV) to measure my possibly too old Ultimate Lithium AA battery , that anything less than 1.79 v indicates that the battery is worn out ?

No. Sorry. It’s complicated. Assuming that you have left EUL unloaded for at least 12 hours (these batteries tend to recover voltage after being loaded), then the OCV can be used as follows: A value around 1.80 Volts is consistent with a new battery (the focus of this post). A cell with an OCV less than 1.60 Volts is basically dead. A voltage reading between 1.60 and 1.80 can be used to estimate the current state of charge, but the relationship is not linear, or perfect, and will be the subject of a future post 🙂

Hi Bob

I would like to ask something which im struggling to get a definite on. I was under the impression Energizer Lithiumss were 2900 Mah. But now im reading all sorts of amounts on various battery sites, from 2900,3000 and even 3500 Mah. I dont suppose thats something you have discovered?

Thankyou very much for your help

Based on my own measurements, I have found the online technical documentation for the EULs to be complete and accurate. See:

https://data.energizer.com/pdfs/lithiuml91l92_appman.pdf

In general, capacity of batteries varies with temperature (lower capacity at lower temperature) and load (lower capacity at higher load). In trail cameras, the load on each battery ranges from ~100 to ~500 mA (day and night). According to Figure 2 in the Energizer Ultimate Lithium Application Manual, above, EULs have a capacity of ~3500 mAh over this range of loads, and over a wide range of temperature. This is consistent with my measurement of total battery energy of ~5.25 Watt-hours.

Hope this helps. And thanks for reading this post and commenting!