Estimating Energizer Ultimate Lithium (LiFeS2) Battery Capacity

LiFeS2 batteries (e.g. Energizer Ultimate Lithium, a.k.a “Lithium Metal”) are popular for use in trail cameras because of their high capacity, ultra low self-discharge rates, and performance at both low and high temperatures. For details, see Trail Camera Batteries: Internal AA-Cell Options. But they are expensive, so we’d like to replace them only when they are near the end of their lives. How can we tell when this is, exactly? In the past, I’ve advocated keeping track of the amount of work (photos and videos taken) on a set of batteries. This method is effective, but what if you have just a battery, and no history? In this post, I show how to get a fairly accurate estimate of remaining battery capacity. I show two methods, both based on a well-timed open circuit voltage measurement: the first with a digital multi meter and a lookup table; and the second with a commercial “pulse mode” battery tester and a correction table. Both tables below.

What Makes Measuring LiFeS2 Capacity Hard?

There are two main reasons that estimating the state of charge of LiFeS2 batteries is tricky. The first is that they tend to slowly recover voltage after load is removed. The second is that estimating the state of charge requires non-linear function that gives imprecise results due to battery variation.

Recovering Voltage

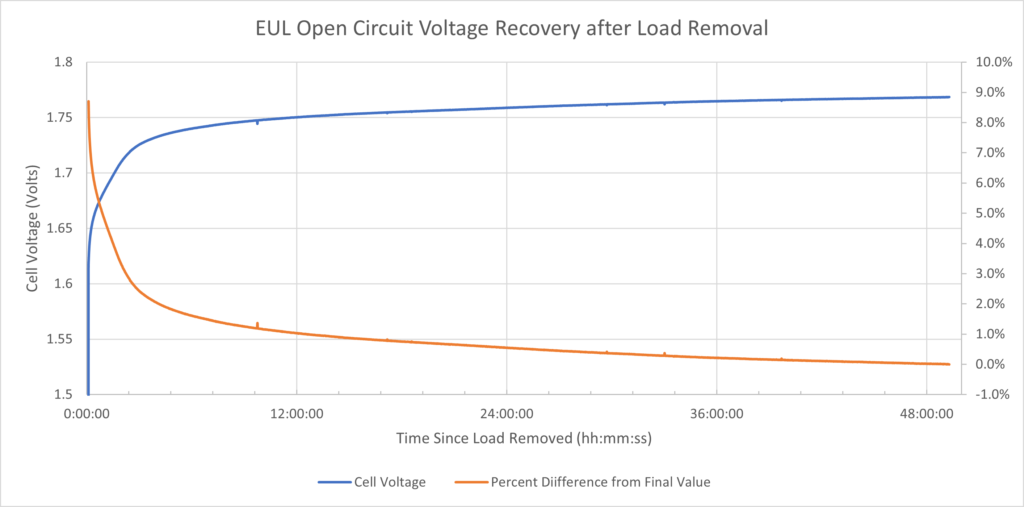

Batteries with most chemistries simply lose voltage as they are discharged. Energizer Ultimate Lithium LiFeS2 batteries, on the other hand, tend to rapidly lose voltage when loaded to a value near 1.5 Volts. But when the load is removed, they can “recover” all or most of this voltage up to 1.6 – 1.8 Volts. See the graph below which shows the open circuit voltage of a LiFeS2 battery vs. time after a load is removed.

This behavior means that it’s critical to measure the voltage of LiFeS2 batteries under no load, and only after the voltage has had time to recover. In practice this means waiting at least 24 hours, and better 48 hours before making a measurement. This is what I will refer to as the “recovered” voltage in this post. Otherwise, instead of getting a useful measurement, all you will get is a sample of the voltage as it’s rising — which depends more on time than the actual state of charge of the battery.

Non-Linear Functions and Scattered Results

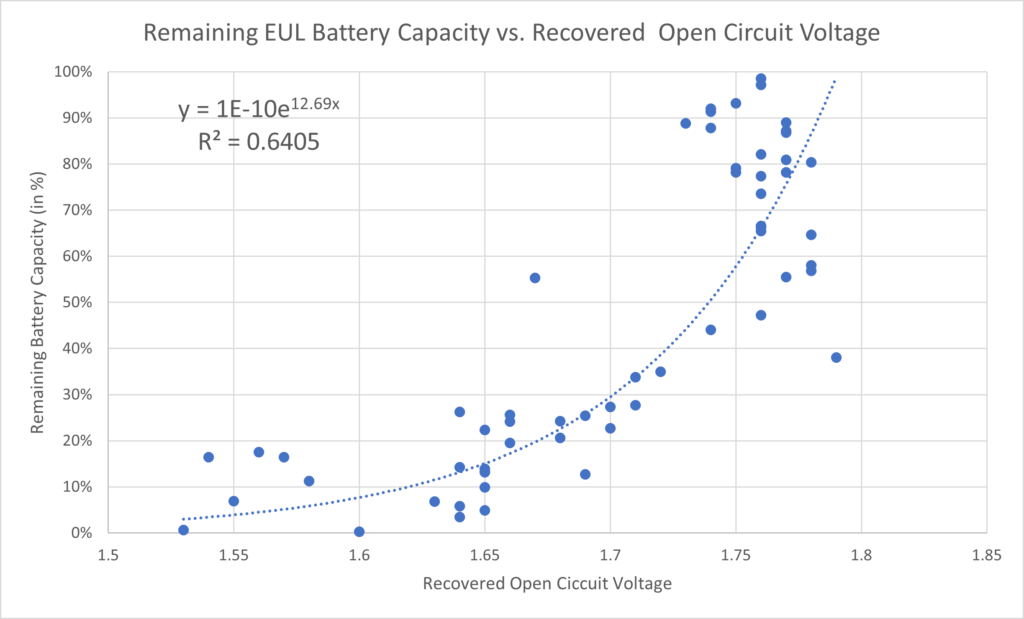

Below I give a graph showing remaining battery capacity vs. “recovered voltage” for about 75 batteries which I monitored through full discharge cycles. Running them until they were dead gave the exact remaining capacity. Unfortunately, it also left me with dead batteries. The cost of data. I also show a curve which I fit to this data which maps recovered voltage to remaining capacity.

Note two features of this graph:

- The best fit curve to this data is not linear. By this, I mean that the capacity dependence on voltage is much larger at higher voltages and higher capacities than it is at lower voltages and lower capacities.

- Battery Variation: I estimate an error of +/- 20% in actual remaining capacity over all voltage values. [I would need more batteries, and more analysis to formalize this error bound]. This error is higher for higher voltages and capacities, and lower for lower voltages and capacities.

This graph also shows the impossibility of using the same function to estimate battery capacity when the batteries are loaded (typically around 1.5-1.6 Volts), vs. when they are not. You can see this in the battery meters of some trail cameras, which show battery capacity apparently plunging as the camera is being used to review photos and videos. The reading on the meter when you first check it is likely the most accurate, though it may also be off if the camera recently triggered, and thus loaded the batteries.

Measuring Energizer Ultimate Lithium LiFeS2 Capacity

I’ve found two methods for estimating remaining battery capacity of LiFeS2 cells based on data that I’ve collected. Both methods require that the battery be left unloaded for at least 24 hours, and better 48 hours prior to making a measurement. Both methods give a somewhat large error, which I have summarized in tables, below.

Using a Digital Multimeter

My data confirms documentation from Energizer suggesting that all the “interesting” output of these batteries occurs within a range of less than 0.3 Volts. I.e. between ~1.5 and ~1.8 Volts. Mapping such a small voltage variation to an exponential function requires a digital multimeter with an accuracy better than 5%, and ideally better than 1%. Use the table below to convert a measured open circuit voltage of battery to an estimated capacity. Note the range shown in parentheses gives the possible actual capacities due to variation in individual batteries. This method is most accurate at the low end of the voltage and capacity range. I.e. a battery that shows up with a voltage under 1.65 Volts is unlikely to have more than 20% remaining capacity. But a battery that measures 1.75 Volts may have an actual capacity of 50 – 90%.

| Measured Recovered Open Circuit Voltage | Estimated Remaining Capacity |

| 1.50 – 1.60 | 5% (0 – 20%) |

| 1.6 – 1.65 | 10% (0 – 30% |

| 1.65 – 1.70 | 20% (5% – 40%) |

| 1.70 – 1.75 | 40% (25% – 90%) |

| 1.75 – 1.80 | 80% (50 – 100%) |

Using a “Pulse Mode” Battery Tester

The ZTS Inc. MBT-1 Multi-Battery Tester makes two relatively precise measurements of voltage: one at no load, and then, a second or two later, at a calibrated load. Based on these two measurements, and battery type, firmware in the tester makes an estimate of battery charge.

With two measurements, this method gives a slightly more accurate estimate of remaining battery capacity than a single voltage measurement, but only by a few percent. Both methods result in relatively large expected errors, especially at the high end of the scale. My measurements suggest that the base firmware gives repeatable, but overly optimistic results. Use the table below to map from the reading on the MBT-1 tester, to a more accurate estimate based on my discharge data.

| MBT-1 Battery Tester Results | A More Accurate Result (Range) |

| 10% | 5% (0-20%) |

| 20% | 5% (0-20%) |

| 40% | 10% (5-25%) |

| 60% | 20% (12-28%) |

| 80% | 40% (25-50%) |

| > 80% | 70% (35 – 100%) |

Summary

Although LiFeS2 batteries have a number of qualities which make them useful in trail camera applications, being able to easily measure their state of charge is not one of them. Waiting for at least 24 hours and preferably 48 hours while the battery is unloaded is critical to estimating the state of charge of these batteries, as it allows the open-circuit voltage to “recover.” Based on measurements of a population of 75 batteries measured during discharge, I give two recipes for estimating state of charge with an error of +/- 20%. The first uses a table applied to an open-circuit voltage measurement with an accurate digital multimeter. The second applies a correction table to results from a commercial “pulse mode” battery tester.

Have you ever had trouble estimating the remaining charge of an EUL battery? Let us know in comments below.

References

Energizer, “Cylindrical Primary Lithium Handbook and Application Manual“

Interesting that one would want to wait 48 hours after the battery has been loaded to measure the power remaining as the voltage recovers. Because of the no load voltage recovery I would think that the pulse loading or looking at the voltage under a known load would give a more realistic view of the health of the battery.

I thought the same thing! But, in data that I collected which I did not report (because it didn’t work), I found that the loaded voltage for any given cell is almost constant (within 0.01 Volts) over most of the discharge, even as the cell-to-cell variation in the loaded voltage is greater than 0.1 Volts. I.e. the cell to cell variation (noise) is about 10x more than change in Voltage over time (signal), making it useless as an indicator of the state of charge.

I also took extensive measurements of the “series resistance” (related to the instantaneous loaded Voltage) of these cells over time. This follows a “bathtub curve”, with the shallow part of the bathtub being very flat. I developed a more sophisticated curve fit that takes into account both the open circuit voltage and the series resistance, but found that it only slightly improved the precision and accuracy vs. a voltage only measurement. Did not seem to be worth the additional equipment required.

The MPT-1 tester does a “poor man’s” series resistance test, but I found this also did not substantially improve the precision or accuracy (even after I corrected it).

I considered writing an in depth “Deep Tech” article documenting these attempts, but decided the audience was likely too small for the additional work. I worry that most people lose interest when I introduce a Digital Multimeter 🙂

Have you been able to sort out how the camera manufacturers estimate battery life? I recently put some used Energizer Lithium batteries into a top of the line trail camera that only wants you to use lithium batteries. The camera rated them at 100% and then they quit 36 hours later.

I have a pretty good idea for Browning and Exodus trail cameras. In these cameras, the firmware bases the battery meter on a linear mapping of the current battery pack voltage to a scale that goes between 0 and 100%. They use a different table for each battery type. In earlier versions of the Browning cameras (e.g. the Advantage series), the firmware special-cased Lithium batteries, and spit out only 5 values (as I recall): 0, 25, 50, 75, and 100%, also based on the current battery pack voltage. In newer models, the Brownings have a full lookup table for Lithiums, as well. Unfortunately, as I have documented, the current voltage value, while the camera is operating, is a poor predictor of the state of charge. In all the cameras I’ve worked with, this estimate is mostly pessimistic. E.g. in new Brownings and our Reconyx WP-9, you can watch the battery meter value plunge as you are reviewing photos/videos in playback mode. This in no way reflects the actual state of charge, which is almost always much higher.

Alternatives include : keeping track of the amount of power consumed by each camera operation; and substracting this from the capacity of new batteries. I prototyped this on the Advantage. It works pretty well, but this was before I had figured out the menu system, so the interface (e.g. for resetting the accounting when new batteries were installed) was obscure, and difficult to remember in the field. Another method would be to take voltage measurements as soon as the camera wakes up, and after it’s been idle for a good long time, and using the table in this post. Or perhaps some hybrid of the two methods. On my list of potential future firmware hacks.

Power consumption should depend at first from the led use, since they go very high on current; you try to average the battery life for low current during sleeping, some current (maybe 50mA ?) during day picture to several amperes with led on (ca 50W ), quantitative prediction are non sense.

concerning the state of charge relation with voltage, the dispersion is so big that its useless for maintaining a camera in the field; which action you take if it remains 40 % or 80% ? a new visit in 15 or in 30 days…then why not switch to rechargeable lithium polymer, available with a 5 v converter inside and capacity at least as big in AA size , directly fitting the cameras (and up to 3.5Ah for the price of energizer)

Thanks for your detailed comment. There’s a lot here, but I will do my best to address all the issues you raise.

* IR LED Power Consumption: You are right that when operating at night, with the IR LEDs on, the camera consumes much more power than taking images during the day — roughly 4-7 Watts vs. 1 Watt (depending on flash setting). This can make it hard to accurately “coulomb count” — as I outline in https://winterberrywildlife.ouroneacrefarm.com/2021/11/10/trail-camera-batteries-internal-aa-cell-options/ My primary point is that how long a battery lasts needs to be measured in work done (photos/videos/night/day) vs. “hours in the field”.

Beyond that, I was aiming for a “rule of thumb” that would be useful in the field. I did by assuming that 20% of images are night images, which is typical for our deployments. Obviously, if a given set has much more, or much less, it will impact the amount of energy used. Of course, it’s difficult to know without going through and counting all of the images, which is not practical in the interesting case that there are a lot of them. As I noted, it would be much better if the camera firmware did this itself.

* Sleep Power: You are right to ask about the power consumed while the camera is “sleeping”. Some small amount of power (less than 1 mW on modern cameras) is consumed keeping the PIR sensor alive, and just enough of the internal processor keep time and to wake up. This is orders of magnitude smaller than the power consumed while taking photos/videos, and can safely be ignored for cameras deployed less than a year. (A fresh set of EULs will keep a camera in sleep mode for over 10 years).

* On the limited accuracy of tracking photos/videos: Again, you have a point. With a large error bar, it can be difficult to know what to do with the data. None-the-less, we find the error associated with simple photo/video accounting, or in the measurements I outline in this post, to be less (for EULs) than the error in the internal battery meter. The threshold at which we “retire” a set of batteries to less critical duty depends on: how often we visit the set; how well we can predict the activity rate at a set; and how important the images are. Often we retire batteries to lighter duty having predicted 50% remaining capacity.

* On switching to Lithium Polymer (or other) rechargeable batteries: I’m a fan of rechargeable batteries! See my posts https://winterberrywildlife.ouroneacrefarm.com/2021/11/10/trail-camera-batteries-internal-aa-cell-options/ and https://winterberrywildlife.ouroneacrefarm.com/2022/04/21/deep-tech-rechargeable-li-ion-aa-batteries-for-trail-cameras/ Still, there are good reasons for using the more expensive, primary EULs. The biggest reason is this — if you are limited to volume and form-factor (inside a standard trail camera, inside a standard trail camera security box) EULs offer the highest per charge capacity of any battery tech — by as much as a factor of two! This while also providing very low leakage, and excellent cold weather performance. For sets which must be left for a long time, over winter, and/or have an unknown activity factor, and/or have unavoidably high false trigger rates, and/or are focused on especially interesting targets, more energy is better. Lately, in doing research for a second book, many of our sets fall into this category.

Having said this, the Li-Ion “AA” rechargeable batteries use just the technique you suggest — with an internal voltage converter to produced the 1.5 Volt/cell of the AA standard. These batteries (or high quality NiMH rechargeable AAs) are great for sets that are visited often; have predictable activity; and low false trigger rates. All this and they fit seamlessly in the camera and lockbox.

If you are willing/able to go with an external battery pack, then the sky is the limit! For example, there are readily available 12V Li-ion battery packs with capacities upwards of 20 Ah! Of course, if you do this, then you have to manage and protect this external battery pack, keep the cable from being chewed, lug around a larger battery, etc.

As with many things, any choice of batteries represents some tradeoff.

And an opportunity for many blog posts!

Thanks for the interesting article and useful reference. In case this discussion is still active:

My Energizer “ultimate lithium” batteries usually measure 1.9V or above under no load, either when new and (when slightly used) after resting. BUT sometimes a used, but rested, one will measure over 2V. (You can trust these numbers; I’m using a good-quality Fluke digital meter.)

What might a reading over 2V mean?

Meter differences? I used my trusty (Fluke Knock-off) Tenma 77-7732 digital multimeter for all my measurements. These include, BTW, measurements of a 134-unit sample of brand new EULs I used in another of my “Battery Series” posts at https://winterberrywildlife.ouroneacrefarm.com/2020/07/10/are-my-new-batteries-really-new/ I plotted a histogram of OCV for these new cells in this post, and the distribution was very tight — almost all between 1.80 and 1.81 Volts, with a very steep tail. It’s possible that our multi-meters differ by 10% — I have not calibrated mine. I also notice that readings on my Tenma tend to increase as the multi-meter’s battery starts to run low — this even before the “low battery” indicator.