How (some) Trail Cameras Fail

Most trail cameras work most of the time. However, the outdoor environment is hard on electronics and some fail. In this post, I review the record of cameras we have used over the years to give an account of symptoms, failure modes, and in most cases, fixes. Perhaps this will help you figure out what’s wrong with an out-of-warranty camera. Even better, if trail camera manufacturers could take this information to heart, perhaps they could eliminate these failure modes from future models!

[Updated 2021-07-19] Added “Disassembly Notes” section at the end of this post with tips on taking some cameras apart.

[Updated 2022-09-19] Added some new failures. Last notice of update on this post, although I will continue to add to it as I become aware of more failure modes.

Overview of Failures

The table below gives a summary of failures and fixes discussed in detail in the rest of this post. Follow hyperlinks in the “Name” column to get to each.

| Name | Symptoms | Failure | Fix |

| Stuck IR Filter | Pink day photos; dark night photos | Cold solder joint on leads for IR filter motor | Reflow solder on IR filter motor leads |

| Digital Image Artifacts | Portion, or all of vidoe or photo frame has “digital” artifacts. E.g. very wrong color, or vertical lines, or “split screen” | (Likely) Main processor failure | Repair not practically possible. |

| Run-On Triggering | Multiple videos with no animal after legitimate trigger | Thermal path between CPU and PIR detector causes self-triggering | Increase delay between triggers; push PIR detector 1 mm up off surface of PCB; tighten CPU heat sink screws |

| Loss of Focus | Over time, photos and videos become blurry and out of focus | Failure of lens, which sometime seem to develop an “astigmatism” (areas that our out of focus) over time | Replace the image sensor lens |

| Early Battery Draining | New batteries fail after a few weeks in the field | Corrosion of small internal battery leads to higher than normal current drain while camera is in “sleep” mode | Remove corroded battery, clean PCB, replace with a new cell. |

| Reset Date/Time | Date/Time reset to some default (e.g. 12:00, Jan-1, 2017) despite being recently set. Other camera settings are preserved | Wearout of the small internal battery prevents real time clock from working | Remove discharged battery, replace with a new cell. |

| Reset Date/Time and Lost Settings | Date/Time and other settings (e.g. “mode”, “video length”) reset to some default value when camera is turned off, then back on (or when triggered) | Corruption of internal configuration file | Hard reset by removing/reinstalling batteries. If that doesn’t work, reload firmware |

| Lost Settings | Menu settings (e.g. “mode” , “video length”, etc.) reset to some default value when camera is turned off, then back on (or when triggered) | Failure of EEPROM | Replace EEPROM with one programmed with factory image |

| Lost Time | Time is off by an hour or more, despite being recently set | Unknown | Unknown |

| Punctured PIR Lens | PIR sensor stops working; water incursion; visible damage to PIR lens | Thin Fresnel lens over PIR sensor is punctured or broken, often by a bird pecking at it; sometimes by a large tooth | Replace Fresnel Lens with replacement from manufacturer |

| Flash Failure | Dark night shots; IR Flash does not come on | Drive transistor for high current IR LED array overheats, melting plastic, opening circuit | Replace drive transistor if possible. If plastic is damaged, time to retire camera |

| No Photos Taken | Despite new batteries, working SD card, correct settings, correct arming, camera takes no photos/videos | Unknown | Unknown |

| Water Incursion | Moisture or condensation visible on the inside of the camera, often in front of camera lens, or LED flash window | Design limitation; failure of gasket systems; crack in Fresnel lens for PIR sensor. | Design problems may not be repairable. Check all gaskets for integrity and proper seals. Check Fresnel lens and replace if cracked. Place camera in security box; or cover with a “roof” to limit water from the top. In very wet (e.g. tropical) environments, consider putting desiccant material inside the camera enclosure |

| SD Card Failure | Camera will not turn on, or freezes, or does not take photos or videos, or runs down batteries in <48hours | SD card is unreadable, unwritable, or returns errors to firmware which cannot be handled | Discard SD card and replace with one that works |

| SD Card Corrupted and Battery Dead | Same as above | Most likely SD card spontaneously fails in camera | Discard SD card. Full format new SD cards in PC before deploying in camera. Quick format, take test photo in camera. |

| Sound Failure | Audio associated with video is missing sound, or is crackly and noisy | Microphone is damaged, or wires have become disconnected | Replace microphone |

| LCD Failure | Loss of one or more colors on LCD screen, or loss of contrast, or lack of backlight | Failure of LCD module in time. Less likely, water contamination of flex cable connector | Remove and clean flex cable connector for LCD screen. Retest. If this does not work, replace LCD module. |

Stuck IR Filter

Many cameras use a motor-driven IR filter to block out IR during daytime photos, while allowing IR to get to the sensor for night time photos. If the IR filter is working, you can hear a faint “click” as a tiny, simplified, electric motor moves the IR filter from one stable position to another, and back.

Symptoms of Stuck IR Filter

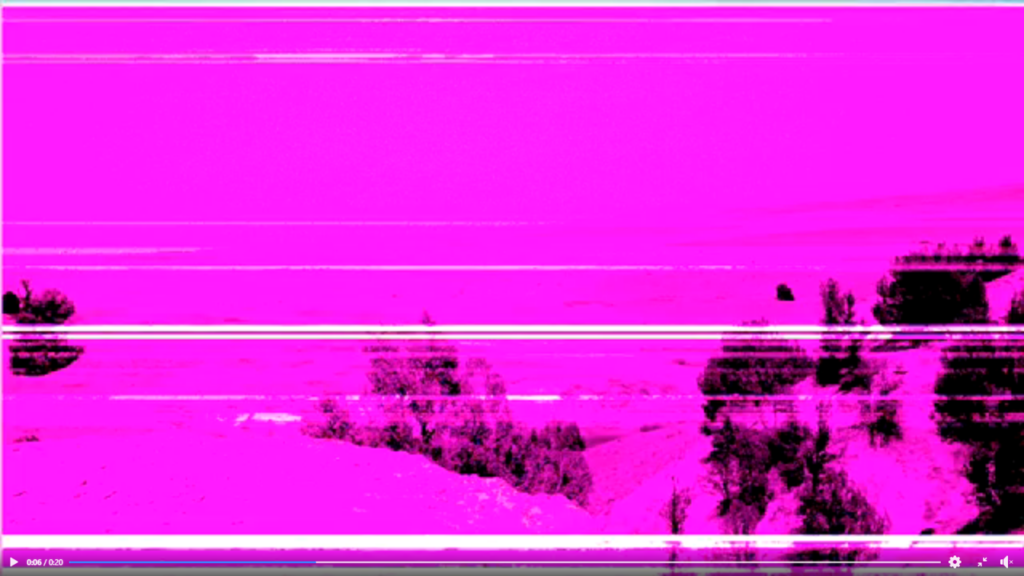

Failures of the IR filter result in two kinds of “wrong” photos/videos:

- If the IR filter becomes stuck while disengaged (not covering the lens and image sensor), nighttime photos will be fine, but daytime photos will be pink. This is because the image sensor is interprets the IR from the sun as “extra” red. This is the problem with the pink panther in the intro photo.

- If the IR filter gets stuck while it is engaged (over the lens and image sensor), daytime photos will be fine, but nighttime photos will be very dark, because the stuck IR filter is preventing IR light from the flash from getting in. This is sometimes misinterpreted as a failed flash unit. It can be differentiated from this case if the flash itself is actually coming on during night shots.

The IR filter is often the only moving part in a trail camera, and therefore subject, in principle, to mechanical failure. Some manufacturers even go so far as to offer models with two image sensors — one with an IR filter, and one without — in part to avoid the possibility of IR filter failure.

Debugging Stuck IR Filter

False Lead: It’s not the mechanical part!

In debugging these cameras, my initial hypothesis was some sort of mechanical failure of the motor system. On investigation, I found that the motor mechanism is refreshingly simple and robust. In all cases of “stuck filters” I investigated, the IR filter mechanism showed every sign of working correctly, as shown in video below.

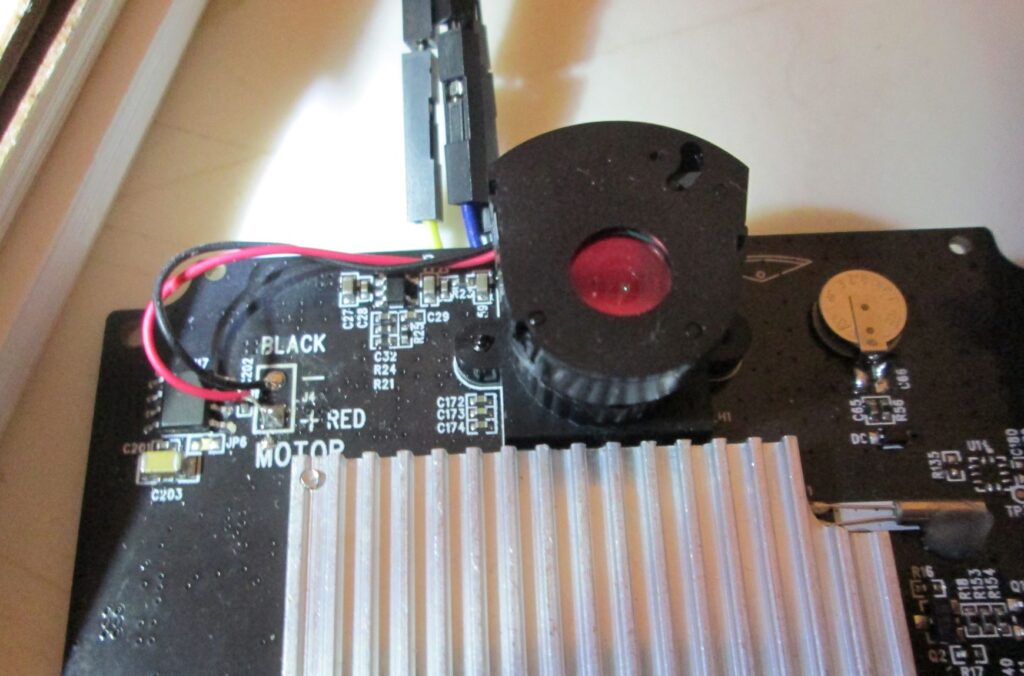

The Real Culprit: A Cold Solder Joint

Instead, the problem has been a cold solder joint between the wires from the main PCB to the IR filter motor. Cold solder joints occur when the solder doesn’t quite get hot enough to melt completely. The connection can look good, and even work well for a while. Over time, however, the connection fails, eventually leading to a sometimes intermittent open circuit. Cold solder joints have a notorious history, but have largely been eliminated by automation from modern, mass-produced electronics. I believe they occur in some trail cameras because of manual soldering of the IR filter motor wires to the PCB, and because at least one of the PCB pads dissipates a lot of heat, and is therefore more difficult and time-consuming to solder correctly.

Fixing Stuck IR Filter

One can sometimes “fix” a cold solder joint by mechanical agitation. Yes. By “banging it.” Unfortunately, the problem is likely to recur as thermal changes and oxidation work their undesired magic. The permanent solution is to open the camera and to use a soldering iron to reflow the solder on the offending joints. Nowadays, I need a magnifying glass (or better, a binocular dissecting microscope) to watch the satisfying point at which the solder melts into a uniformly shimmering mass and wicks completely around the pad on the circuit board and the wire to the IR filter motor.

Digital Image Artifacts

Symptoms of Digital Image Artifacts

In this failure mode, reported to me by followers of this web page, the image files written to the SD card have “digital image artificats”. These artifacts may include bizarre coloring, visually noisey or solid horizontal stripes, or multiple “images” or pieces of an image in the same file. These artifacts are “digital” in the sense they don’t reflect the “analog” artificacts that might actually occur in an image. E.g. poorly lit, washed out, blurry “blobs” or eyeshine reflections.

Digital image artifacts may affect all of the photos and videos taken by the camera, or may only affect a subset of images. They may appear consistently through a whole video, or may change, flashing in and out, between portions of a video.

Debugging Digital Image Artifacts

Sometimes digital artifacts will result in images with pink color, also seen in “Stuck IR Filter.” We can rule out “stuck IR filter” if only a portion of the image is pink, or if the pink coloration occurs in night time video.

I have not debugged one of these failures to a root cause, but I believe these digital image artifacts are caused by a failure of the video memory used by the main processor in the camera to process the image on its way to becoming the .jpg or .mp4 files that are written to the SD card. The consistent failure of even a single bit can lead to incorrect color, and address decoding errors can lead to portions of the memory (and therefore the image) not being updated at all, and thus having only uninitialized data.

Fixing Digital Artifacts

Unfortunately, there is not a practical way to repair cameras with this problem. In principle, one could replace the main processor itself, but his part is not available on the consumer market, and would require lab equipment and expert time to remove and replace. One could also replace the entire main circuit board, but this circuit board is the bulk of the cost of the camera, so you’re better off with a new camera.

Run-on Triggering

Symptoms of Run-on Triggering

This is a problem I have seen in several cameras. I even featured one of these failure modes, in which a camera suddenly “photos itself to (battery) death” in an earlier post. See: Runaway Trail Camera. I have recently seen a variant of this problem in Browning models BTC-7A and 8A. The camera takes a video on a legitimate trigger, but then continues to take videos constantly for up to several minutes. This even though the animal has long left. We have seen this failure develop in cameras over time. That is, initially the camera operates correctly, but over time, it begins to get more and more of these “run-on” trigger events.

Debugging Run-on Triggering

After some investigation, I believe this problem is caused by unwanted coupling of heat between the microprocessor (used to process the video and compress it into MPEG files) and the PIR sensor. As cameras get smaller, designers are more likely to put the heat-generating processor closer to the highly heat sensitive PIR sensor. This at the same time they are using increasingly sensitive PIR sensors (to capture all those animals!) , and processing higher resolution videos (generating more heat from the microprocessor). The PIR sensor is sensitive to changes in its local temperature, which can cause it to trigger falsely.

In the scenario I have documented in the lab, the processor heats up while processing the first video. Then the heat from the processor travels through the PCB to the PIR sensor. The PIR sensor starts becoming warmer at a rate that exceeds 2 degrees Celsius per minute (the rated maximum spec on the PIR sensor). This causes the PIR sensor to immediately trigger, which causes the processor to get even hotter, and so it goes. Fortunately, the PIR sensor is only sensitive the the rate of change of its ambient temperature. Once the the sensor reaches an equilibrium temperature, it stops triggering, and the run-on stops.

I think the root causes of the problem are some combination of:

- insufficient margin in the thermal design of the camera

- a possible design or manufacturing error in which the PIR sensor is placed flush with (and therefore in tight thermal contact with) the PCB

- failure of the the thermal bond between the processor an the heat sink, causing PCB, and with it the nearby PIR sensor, to get hotter

Update 2021-11-10: We noticed that this problem seems more common in Browning Spec Ops Advantage (BTC-8A) vs. Recon Force Advantage. Turns out that the BTC-7A has a series of cutouts in the PCB around the PIR sensor which limit heat flow (see photo above). The (earlier?) BTC-8A PCB does not have these cutouts. Increased heat flow through the PCB in these cameras explains the increased prevalence of this problem.

Update 2024-02-03: After a long hiatus in Browning trail cameras, this problem has made a comeback in certain instances of the Elite HP5 SpecOps and ReconForce cameras. These cameras have a substantially different internal design vs. the Advantage series cameras I focused on in the original post. Gone is the CPU heat sink, and the PIR sensor is now on a separate “daughter” PCB. It is possible that pushing the PIR sensor a mm or of above the daughter card may help in these cameras as well, though I have not yet tried this.

Fixing the Problem

One can work-around this problem by setting the “Photo Delay” parameter (the minimum amount of time the camera will wait before re-arming) to be larger. This allows the camera to cool down a little before waiting on the PIR sensor. Unfortunately, this also means that the camera won’t retrigger quickly if the animal is still there.

I have had some success in reducing (if not completely eliminating) the problem by:

- tightening the screws which help hold the heat sink in contact with the processor. This allows more of the heat generated by the processor to be dissipated by the heat sink, reducing the heat flow through the PCB, and ultimately to the PIR sensor.

- unsoldering the PIR sensor; pushing it up off the PCB by a millimeter or so, and resoldering. This increases the thermal resistance between the PCB and the PIR sensor, thus reducing heat transfer.

Loss of Focus/Photo/Video Clarity

Symptoms of Loss of Focus

I have seen this problem now in several Browning models (e.g. the Recon Force Extreme BTC-7FHD-PX, and the newer Recon Force Edge BTC-8E), but I expect it to be endemic to exist in other types of cameras as well. Initially, the camera takes great, crisp and clear color and night time photos and video. However, over time, the quality of the images deteriorates as both the photos and videos become blurry and out of focus. On careful inspection. one can sometime see that only a portion of the image is blurry and out of focus.

Debugging Loss of Focus

After much head scratching, I came up with a simple experiment that at least isolated the problem. I took a series of photos of myself at varying distances from the camera, with and without a “corrective” magnifying lens from a pair of reading glasses taped in front of the camera’s own lens. I found that in all the photos without the corrective optics, the photos were blurry and out of focus. However, for some of the photos taken with the corrective lens, the photos were in perfect focus.

The fact that the corrective lens fixed some of the photos ruled out any problem with firmware or processing hardware. More subtly, it ruled out the possibility of lens becoming scratched, cloudy, or perhaps covered with condensate.

This problem remained mysterious to me because the “fixed focus” plastic lens mount and lens seemed so solid. Not so.

Details on the Lens Assembly

As shown in the photo below, the “fixed” lens assembly is actually two pieces. The first piece is a Type-S, or “M12” lens mount, which attaches to the PCB with a pair of screws. The lens mount has a 12 mm hole, tapped with a 0.5 mm pitch set of threads. A small lens screws into these threads. The amount that the lens is screwed-in determines its distance to the sensor, and therefore the optical focus.

A Theory Revised

My original theory was that the lens was somehow rotating in the mount (possibly due to improperly installed glue), causing the camera to lose focus.

Subscribers to the blog (thanks Ulli and Dan!) had this problem and agreed to test out my early theory. They found that the glue was solid. Moreover, that since the IR Filter motor is stuck to front of the lens, and it had not rotated, neither could the lens. Finally, when they turned the lens (a good half turn) they found that it fixed the focus in one part of the image, but made it worse in other parts of the image.

This new data required a new theory, and here it is: the lens itself is deteriorates over time. This is not surprising, given the number of thermal cycles these cameras often experience, and the low-cost, plastic housing for the lens components. I’m imagining that the lens assembly somehow goes a little out of alignment, causing the image to become defocused. I have verified, in any case, that replacing the lens fixes the problem.

Fixing Loss of Focus

This repair requires replacing the image sensor lens. In the repair I did, I used a lens from a “parts camera” as a replacment. I am currently working on a post that includes sources for replacement lenses. Until then, I would not recommend simply buying an S-type, M12 “compatible” lens as a replacement. Trail cameras seem to rely on a unusually compact lenses, and most of the lenses I’ve found on line are too long, and won’t fit in the camera. Stay tuned.

The repair involves getting into the camera, removing the main circuit board, removing the IR filter motor assembly from the top of the lens (it’s held on by double sticky tape). I replaced the whole lens mount/lens assembly, but it’s possible to just change the lens. The latter requires removing the glue along the threads. Dan advises the use of small screw driver heated with a flame to soften the glue. Future post will include details on setting the focus correctly.

Early Battery Drain

Symptoms of Early Battery Drain

Occasionally, cameras seem to drain batteries very quickly. This whether they are taking photos and videos or not. A modern trail camera should take tens of thousands of photos and several hours of video, even at nighttime with the flash, on a new set of AA Energizer Ultimate Lithium batteries. It should last in the field without taking videos or photos (just waiting, with the PIR sensor active) for years.

We recently ran across this problem after a long hiatus when retrieving a “pandemic” camera that had been in the field for over a year. Unfortunately, this Browning Strike Force HD Pro (BTC-5HDP), with a new set of 6 Energizer Ultimate Lithium batteries exhausted its batteries, somehow, after less than a month. This was particularly frustrating, since it was in a really good spot! During the month it worked, it got some great photos, and would have undoubtedly gotten many more had it not failed. The silver lining is that I got to investigate this failure mode in detail.

Debugging Early Battery Drain: Typical Trail Camera Operating Current

Trail cameras consume power in two ways: while taking video or photos; and while waiting to take video or photo. Actually taking the the photos/videos consumes much more power than simply waiting. In this camera — the active power is about 650 mW, whereas the “sleeping” power is close to 650 uW — or 1000 times less.

The camera in question used the batteries at greater than 60 times the expected rate. This is very difficult to do in the active state — since consuming ~60 times the power is hard to do with the available components, even in failure. This caused me to suspect the “sleeping” power. Since this power is very low to start with, there are several possible failure modes which could consume little absolute power, but still much more than the intended idle power. Since idle power is consumed all the time, even a small amount can drain the batteries over a series of days or weeks.

I used my digital multimeter to measured the current (which is proportional to power) consumed by the problem camera. I happened to have (from the same trip) a camera of the same model that had not failed, which I was able to use as a reference. I confirmed that the current (power) consumed by both cameras in “active” modes — that is taking photos and videos, or displaying the user interface — was very close.

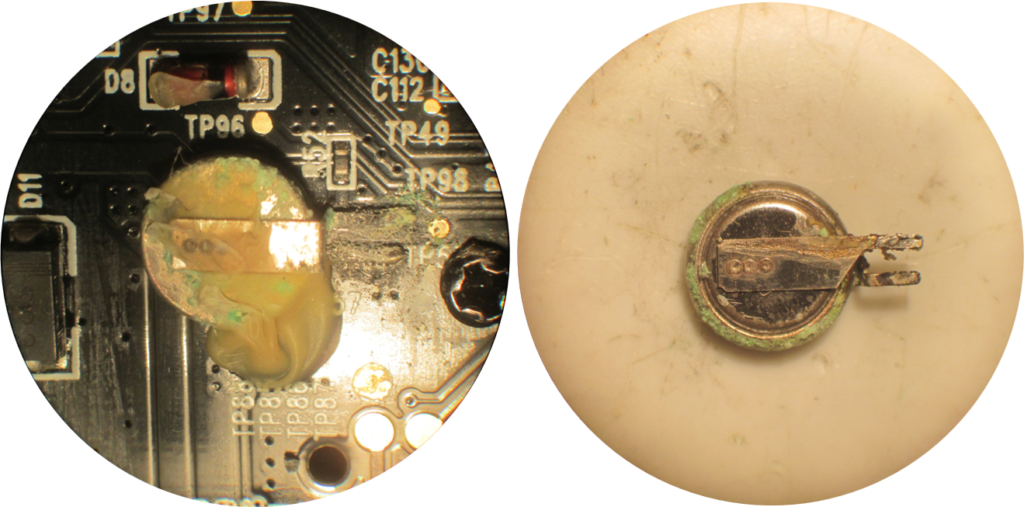

Then I moved on to the “sleep” mode and found some strange behavior in the problem camera. Unlike the good camera, which consumed a constant ~50 uA, the problem camera started out consuming 3 times this amount. Over time, it seemed to approach the lower figure, but the long time constant (10’s of minutes) suggested some energy storage element — a capacitor or perhaps battery — was not working properly.

On visual inspection, I found a small battery on the PCB with some corrosion between the positive and negative leads. This battery is used to power the real-time-clock (RTC) (date and time) device while the user is changing the main battery pack. This battery is designed to be “trickle charged” at a very low current (< 10 uA), and can power the RTC for several hours.

In the case of the failed camera, some bit of moisture lead to corrosion between the positive and negative battery pins. Alternatively, the battery itself failed due to thermal cycling, and started to leak. Whatever its source, the corrosive mixture created a parasitic circuit between the battery pins. This “short” drained the battery and caused the charging circuit to try to draw more current as it tried to charge the small battery from the main battery pack. After 30 days of doing this, the main battery pack was completely drained. Diabolically, in the intervening year, the corrosive mixture dried out and became less conductive, masking the original failure mode.

Fixing Early Battery Drain

I was able to find a similar, 3V, rechargeable, surface mount battery online (see references) — the Seiko MS920T-FL27E for a couple dollars. It is slightly larger than the original cell, but none-the-less fits on the PCB, and has a compatible set of pads. I removed the old battery using some solder wick, cleaned up the board, and then installed the new battery. The current draw in “sleep” is now back around ~50 uA, and the new battery maintains the RTC while I’m swapping the main battery pack.

Reset of Date/Time

Symptoms of Reset of Date/Time:

Date and time on camera are incorrect, appearing as the pre-set default (e.g. 12:00 am, Jan-1, 2017) , even after being properly set. Depending on the type of camera, the data and time may go awry only during changes of the primary battery pack, or even with the primary battery pack installed (and charged). This problem usually develops after cameras have been used for several years.

Debugging Reset of Date/Time:

Verifying this problem is done by opening the camera and measuring the voltage across the two terminals of the internal battery. See photos in “Early Battery Drain” section, above, for an example of what these batteries can look like. Assuming a 3 Volt battery, a measurement below ~2.7 Volts indicates battery is discharged.

Cause of Reset of Date/Time

In addition to the main battery pack, most trail cameras have a small internal battery permanently mounted on the PCB. This battery or ultracapacitor provides continuous power to an ultra low power “real time clock chip.” In some cameras, this battery or ultracapacitor is rechargeable, taking a trickle charge from the main battery pack. In other cameras, the battery is not rechargeable. In either case, failure of the internal battery (either due to charge/discharge cycles, or just running out of power), removes power from the real time clock chip, causing the camera firmware to revert to the default, preset value.

It is possible that extreme temperature fluctuations, hot or cold, may lead to early failure of the small internal battery.

Fixing Reset of Date/Time

This problem can be resolved by replacing the battery on the PCB. This procedure is the same as described in, “high battery consumption.” The first, and most important step is to find a proper replacement battery. A non-rechargeable battery should never be used as a replacement for a rechargeable battery. I do not have samples from very many cameras, but the table below summarizes what I know. If you find other replacements for other cameras, led me know in comments below. Ideally, the battery will be marked with a manufacturer part number.

| Camera | Markings | Type | Replacement(s) |

| Browning BTC-{7,8}A | ELNA 3.3V 0.2F | Ultracapacitor | ELNA DCK-3R3E224U-E, KORCHIP DMS3R3224 |

If the battery is not labeled, there are other ways to determine whether the battery is chargeable, or not, and the nominal voltage.

The failure mode can provide insight into the battery type. If the camera loses track of date/time even when primary batteries are installed and charged, there is good chance that the RTC battery is not rechargeable.

Alternatively, if it only loses date/time when primary batteries are removed, it is likely rechargeable. To be sure, use a mulitmeter to measure the battery voltage with and without the main batteries installed. If the voltage goes up when the primary batteries are installed, the internal battery is likely rechargeable type.

I have only found 3 Volt batteries in the trail cameras I’ve looked at, but this is no guarantee (and may change over time – this post written in 2021). For cameras which recharge the internal battery, measuring voltage across battery terminals with the primary batteries installed will show slightly above the nominal voltage. Unfortunately, measuring a dead battery won’t tell you what the charged voltage should be.

Reset Date/Time and Lost Settings

Symptoms of Reset Date/Time and Lost Settings

When the camera is turned on, or when it triggers, the Date/Time and internal settings reset to some default value.

Note that this symptom is different than the “Reset Date/Time” failure in that both the clock and the camera settings are affected.

The camera parameters are settings are stored on an internal file-system based on an EEPROM (Electrically Erasable Programmable Read Only Memory). This memory holds data even with power is off. When you change the camera parameters and turn the power off, the updated parameters are supposed to be stored in a file on EEPROM. When the camera is turned back on (or triggered) the parameters are read from the file.

Thanks to blog subscriber ShannonW for her help in debugging and testing the fix for this problem on her BTC-7A camera.

Debugging Reset Date/Time and Lost Settings

To verify this problem, it’s easiest to: turn the camera on; change one or more of the settings from their default value; turn the camera off; turn the camera back on again; check settings. If your changes have been replaced by default values, then your camera has this problem.

With this failure, for some reason, the settings are not being correctly stored or retrieved by the camera. We know that the EEPROM device itself hasn’t failed completely because it also contains the program that allows the camera to turn on and respond to the menu. These EEPROM devices do have a limited number of write cycles — but the limit is very large (100,000), and the device is only written if parameters change. It seems very unlikely to me that anyone would exceed this limit even with heavy, long term use of a camera.

Instead, the underlying problem could be a corrupted initialization file which is confusing the firmware. In response to this confusion, the firmware reverts to the default settings (and date/time).

Fixing Lost Settings

- Reset the camera by removing the battery back; waiting for 30 seconds; turning switch on and off; replacing battery back.

- Reload the firmware, which should reset the EEPROM contents.

Find the firmware at the manufacturer website and install per manufacturer instructions. This will definitely reset all the camera parameters. But, with luck, rewriting the firmware will over-write whatever got corrupted in the current EEPROM, and the camera will start working again.

Reloading Firmware for Browning Recon Force Advantage (BTC-7A) and Elite HP5 Cameras

If you have a Browning Recon Force Advantage (BTC-7A), or Elite HP5 with this problem, you may find that there are no firmware images for this camera on the Browning website. However, I did recreate the factory firmware images for these cameras other projects (IR to White Flash Trail Camera Conversion and Adding Features to Browning Elite HP5 Firmware. You can find it at my BTC-7A-Firmware-Images repository and Elite HP5 repository on github.com

Follow directions for downloading and installing firmware in this document. You are looking for the “Baseline” firmware.

Lost Settings

Symptoms of Lost Settings

Very similar to Reset Date/Time and Lost Settings. In fact, a good way to figure this out is to try updating the firmware. If it fixes the problem, you are in luck. But if your camera persistently fails to remember new settings, then you have a problem.

Debugging Lost Settings

The easiest way to do this is to simply change one or more of the camera settings; verify that you have made the change; turn the camera off; then turn it back on. If this happens, the next step is to try installing new firmware. If this doesn’t fix the problem, then it is very likely that the EEPROM (Electrically Erasable Programmable Read Only Memory) — the device that stores the camera firmware, as well as files with settings value, has failed in a way that makes it “read only”. The firmware tries to write new settings (or new firmware), but the EEPROM device won’t take them.

Fixing Lost Settings

See my post: Deep Tech: Repairing EEPROM in Browning Trail Cameras and video below.

Lost Time

Symptoms of Lost Time

This failure is similar to “Reset of Date/Time” failure in the date and time are incorrect. However, in this failure mode, the date and time are merely “off” by a number of hours, vs. resetting to a factory default value. So far, we have only observed cameras losing several hours, never gaining hours. Note that the time being off by a small number of minutes over the same period is a “feature” of the battery-powered RTC design, which accrues some drift in its internal time base.

Debugging Failed Flash

I am still in in the process of collecting data on this failure mode, which happens in our sets relatively rarely. Here are some questions I’m trying to answer:

- Does the loss of time occur in discrete events or as continuous, gradual slowing of the rate of incrementing?

- Assuming errors occur in discrete events, is there any correlation in the “time” at which these events occur in a population of failures?

- Assuming errors occur in discrete events, are they associated with any environmental anomalies (e.g. much higher or lower temperature)

- Having lost time once, does the camera ever spontaneously get the correct time back again (without being reset)?

- Having lost time once, is a particular camera prone to losing time in the future?

If you have answers to any of these, please respond in comments, below!

Broken PIR Sensor Lens

Symptoms of Broken PIR Sensor Lens

Usually damage to the PIR sensor lens is obvious on inspection, and may involve other cosmetic damage to the camera. These thin pieces of plastic can be punctured by birds, or by the teeth of animals. They may also become brittle and crack on extended exposure to direct sunlight due to UV damage.

If damage is more subtle, you may first notice poor PIR sensor performance and/or moisture in the camera.

If lens is damaged, it’s important to take your camera out of service ASAP, as water can easily leak in and cause more (possibly irreparable) damage. Hopefully, you catch this problem before that!

Fixing Broken PIR Sensor Lens

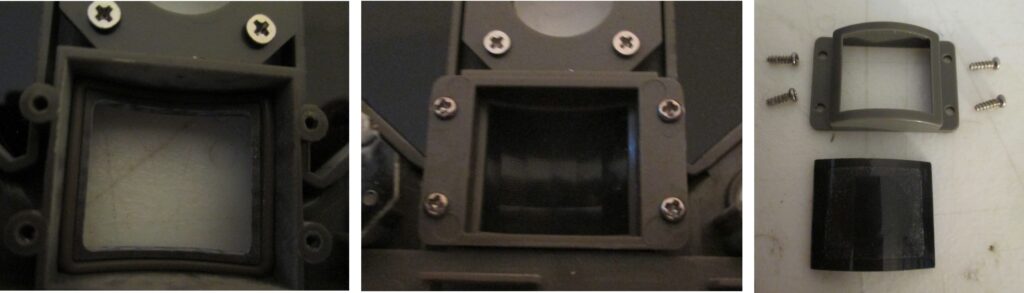

Fortunately, several manufacturers, including Browning (see References) offer replacments for broken PIR sensor lenses. Find and order a replacement and follow manufacturers instructions for replacing. You will need to disassemble the camera to get at internal fasteners and gasket. Photo below shows a typical seating mechanism for the PIR lens.

Note that the PIR lens is highly engineered. It features an array of Fresnel lenses in a very particular orientation and a camera-specific focal length. Your best bet is a manufacturer replacement for your camera. A part from another manufacturer may “work” on your camera, but may not be as good as the original part. A piece of black plastic is right out 🙂

Readers of this blog have had some success making replacement PIR sensor lenses by cutting a readily available Fresnel lens to fit their camera. If you do this, use what’s left of the old lens as a template, placed in the middle of the new lens, and carefully cut around the center. See, for example: PIR FRESNEL LENS_PF16-12012-WHITE available from DigiKey. Note that the lens pattern, will be different on this part than on the OEM part, so the detection behavior may be different.

Preventing PIR Sensor Lens Damage

- Bird Attacks: Some bird species seem more interested in pecking at trail cameras than others. Chances are if your camera is damaged by one of these types of birds, and you put it out again, it will be attacked again. To avoid this, you can try attaching “spikes” around the PIR lens (but obviously out of the field of view of the image sensor).

- UV Damage: The plastic material used for PIR sensor lenses will become brittle and crack due to UV damage from prolonged sun exposure. This is another good reason to avoid setting your camera up so that at faces directly into the sun.

Failed Flash

Symptoms of a Failed Flash

I’ve only seen this problem in older Moultrie model. The flash stopped working, and the nighttime photos were very dark or completely black. I determined that the IR LEDs were not working by testing the camera in a dark room, and looking for a faint red glow from the IR LEDs. Alternatively, you can take advantage of the IR sensitivity of most digital cameras to test for IR light by looking at the camera under test through the camera viewfinder screen. It also helps to have a working trail camera to compare to.

Debugging Failed Flash

When I opened up the camera, I could see that the power transistor driving the LED array had gotten so hot that it had melted the plastic housing for LED PCB, and then failed at some point.

Fixing Failed Flash

I might have solved the problem by replacing the flash PCB. Unfortunately, the melted plastic kept a new PCB from fitting into place, so I ended up turning this unit into a “parts camera”.

Water Incursion

Symptoms “Water Incursion”

Water, or more typically moisture, can sometimes find its way inside the camera. Symptoms include visible condensation on *inside* surfaces. The can include the inside of the camera window, or inside surface of the Flash LED window. Moisture can also damage sensitive electronics, as well as cause corrosion of connections. Suspect water damage if the operation of the camera seems flaky; menu cuts out; camera spontaneously resets itself; and especially some combination of apparently unrelated symptoms.

Debugging “Water Incursion”

“All” you have to do is figure out where the moisture is getting in, and fix it. Here are things I would check. The details vary by camera type. I’ve used a Browning Recon Force Advantage (BTC-7A) as a specific example

- Fresnel Lens for PIR Sensor: can become cracked over time.

- Look for signs of corrosion or oxide buildup on the circuit cards in the camera

Here is a recent example of a camera that stopped triggering. The problem turned out to be a circuit board trace that had corroded away, disconnecting the processor from the PIR sensor.

There are 5 sets of “gaskets” on the BTC-7A that I’m aware of:

- The rubber plugs that seal each of the 6 recessed holes for the screws which hold the front and back case pieces together

- The gasket that seals the battery compartment. This is on the case, around the slot where the battery carrier snaps in

- The gasket that seals the the fold-out door.

- The gasket between the front and back housing pieces. This ~1mm piece of rubber get sandwiched between the housing pieces.

- The gasket around the Fresnel lens/window for the PIR sensor. Getting at this requires taking the main circuit board out, as well as the Flash LED board, to expose a plastic piece held in by 4 screws. While this out, take the opportunity to double check the integrity of the Fresnel lens. See photos in “Broken PIR Sensor Lens”

Check that all of these are clean, undamaged, and properly fitted.

If a careful visual inspection doesn’t turn up any source of leak, you may have to resort to some variant of the “dunk” test. For example, on one of my homebrew DSLR enclosures, I “floated” (just) the front plate (including the barrel and window for the main camera) in a pot of water. Sure enough, after a couple of minutes, I found sources of leaks. I haven’t done this with one of the commercial cameras, but, in principle, I can imagine removing enough of the camera innards to be able to “float” the bottom and top cases. If you do this, make sure that there are no electronics to batteries to get wet if water gets through.

Fixing “Water Incursion”

With luck, a problem with a gasket can be fixed by cleaning and/or resetting the problem gasket. Missing hole plugs for the BTC-7A can be replaced as in my post Inside the Browning Recon Force Elite HP4 (BTC-7E-HP4). Note that not all cameras require these. If a gasket has been permanently damaged, replacement is the only option. I have used the online O-Ring Store as a source for O-rings of the type found sealing the Fresnel lens. You’ll have to measure the size yourself. If you take this path, I recommend “bracketing” the size with slightly smaller and slightly larger replacements to increase the chance you have something that works.

In the absence of a replacment, you may be able to make do with a small, continuous bead of silicone caulk. Done caerefully, this is as good as a gasket in sealing the front and back enclosure halves. It does make future disassembly more difficult, and will require replacement on reassembly.

Another easy solution is to keep water off of the camera. We always put our cameras in steel security boxes, which do a good job of deflecting water from above or below. Others have fashioned little “roofs”, placed above the camera, to deflect rain.

Finally, if all else fails, for “mild” moisture incursion, you can use silica gel packs to soak up moisture that does get in. This solution is relatively easy to apply to a typical homebrew cameras. Unfortunately, there’s typically not a lot of space inside a commercial trail cameras for “extra stuff.” Putting them inside the case is problematic because it requires opening the case to replace them (and they do need to be replaced and re-dessicated to remain effective). I have found that Reconyx sells “Desiccant Sheets“. These will work for cameras other than Reconyx, as long as they can be placed inside the “water proof” volume of the camera. For example, I found that these sheets will (barely) fit under the battery tray for our Browning cameras.

If your camera is malfunctioning after a water “incident” you may be able to repair. Start by visually inspecting the circuit boards for signs of corrosion and water damage. If you find these, use a cotton-tipped swab and some isopropyl alcohol to gently clean the corrosion from the board. Pay special attention to the internal coin cell battery used to maintain the real-time-clock (see “Early Battery Drain” section in this post).

Unfortunately, some water damage may to irreparable harm to the circuit board and/or components.

No Photos Taken

Symptoms of “No Photos Taken”

A problem (so far) for the mystery bin. In these cases, we set up the camera, following a checkoff list which includes verifying that:

- the camera has good batteries,

- the camera powers on

- the LCD comes on

- the camera has initiated its “countdown” to automatic triggering.

- the SD card is relatively new, and has been formatted in the camera — typically right before arming it in the field

None-the-less, when we return, weeks later, full of expectation, we find that the camera has taken zero photos. None. Not even of us finishing the setup. And, yes, the batteries are still good.

Debugging “No Photos Taken” (a work in progress)

We have experienced this most frustrating type of failure several times, primarily on Exodus trail camera models. The problem is intermittent and not reproducible. The SD card is empty, with no files, as it was after being formatted in the camera before the final arming operation. I have used several disk recovery tools and never found any indication that the camera had written anything new. The SD card itself is fine. Indeed, after being turned off and back on, the same camera (with the same batteries) can record to the same SD card.

The good news is that this problem happens very rarely. The bad news is that without being able to reproduce it, I have been unable to get to a reliable root cause. Possibly an obscure firmware bug or error case in the camera startup sequence? I’m all ears, internet!

SD Card Failure

Despite their small size, SD cards are, themselves, a complex computer system with memory, processing, and a great many internal error cases. The firmware inside the SD card allows the billions of fundamentally unreliable, “storage cells” to appear to the trail camera as a reliable data storage device. Sometimes the errors win.

Symptoms of “SD Card Failure”

- Camera will not turn on: Turning a modern trail camera “on” results in a whole pile of firmware being run before you see the “splash” screen. This code incudes internal checks of the hardware, including the SD card, to make sure they’re working. A failed SD card can return a fatal error during one of these checks. Such errors happen so early in the software “boot” process that the screen isn’t ready to report the error (as it does if the SD card is missing completely). The only recourse the firmware has is to turn the camera off and hope that things get better the next time the switch is flipped.

- Camera Freezes: Something similar can happen while camera is reading SD card contents. In this case, if it gets a fatal error it can’t (or isn’t programmed to) fix, it may just “freeze” the camera, requiring a reset of the on-off switch, or even removing and replacing the battery pack.

- Early Battery Draining: If the camera freezes in the middle of trying to write a video or take a photo, it will not go back to sleep, and will consume as much power as it would if it were taking a video or photo. At this rate, it will draw down a new set of batteries in less than 24 hours. Note this is a much faster rate than is caused by a failed internal RTC battery (above).

Debugging “SD Card Failure”

Because SD card failure can be intermittent, good debugging hygiene is required to track down their failure. By this I mean keeping good records of what you changed, and what happened. Certainly, symptoms above suggest potential SD card failure. In general, the best practice is to put known-good batteries (or an external power supply) to eliminate low battery as a possible problem.

Remove the SD card from the camera and try another SD card which you know works. If this fixes the problem, put the old SD card back and see if problem comes back. If it does, you have your culprit.

You can try putting the SD card from the camera with symptoms above into a different camera to see whether the symptoms follow the SD card. Unfortunatley, I’ve seen cases where an SD card would (at least appear to) work fine in one camera, but not in another, so this may not be a reliable test.

Fixing “SD Card Failure”

It is possible that reformatting a failed SD card in a PC (long or short format type) will “repair” a failed SD card. However, given the opportunity lost in an SD card that fails in the field, and their relatively low cost, we have taken to a “1-strike” policy. Any time, including the first time, an SD card fails we discard immediately. If you do try to recover an SD card by reformatting it, make sure to mark it in some way so that you will know (definitely!) to discard it if it fails twice.

Corrupted SD Card and Dead Battery

I’ve updated this section based on more evidence and a lot more work to debug and fix. See full post at: Fixing Browning Edge, Elite HP4 and HP5 SD Card Corruption. I’ve included a synopsis of the post here.

Symptoms of Corrupted SD Card and Dead Battery

- A Browning Edge, Elite HP4, or Elite HP5 Trail Camera is given new batteries, and a recently formatted SD card, and set in the field

- When the camera is retrieved the batteries are dead. The the camera will not turn on unless the battery pack is removed and re-inserted

- The SD card cannot be read by the camera. Indeed, the camera often will not get past the “splash screen” while the SD card is installed

- When placed in a PC, the SD Card is unreadable by the file system. The PC asks whether you want to format the SD card

- Forensic analysis of the SD card with disk recovery tools (e.g. Stellar Photo Recovery) show a small number of intact images/videos. Invariably, these start with IMG_0001.mp4 . There are certainly not the number of files one would expect from a full set of batteries.

- We have never seen this problem in the earlier Browning Advantage camera models.

- This problem occurs with cards as small as 32 GBytes, but also on 64, 128, and 256 GByte Cards

Debugging Corrupted SD Card and Dead Battery

These intermittent, rarely occurring problems are invariably difficult to debug. Starting with the symptoms, I was able to conclude:

- At some point during the cameras deployment, often after taking only a single video, camera corrupts the SD card. This makes the card unreadable by the camera.

- The camera firmware, on encountering the corrupted SD card, crashes. One result of this crash is that the camera firmware stops functioning. Critically, it does not run the timer which turns the camera off between triggers. Left in the crashed state, the camera consumes the battery charge in about a day.

- The problem is not related to the difference in file system formats between cards of 32GBytes and smaller, which use a FAT32 format, and cards 64 GByte and larger (which use the ExFAT file system format). This points to a problem “further down” to software storage stack.

Reproducing the Failure

To get any further, I needed to reproduce the problem in the lab under conditions and with tools that would help me figure out what was going wrong.

I found that I was able to elicit infrequent behavior from the camera that hinted at read/write errors to the SD card by:

- Erasing the SD card using the Delete All menu

- Arming the camera

- Triggering the Camera

- Taking one 5 second video

I performed this sequence many times while examining the diagnostic print messages. Most of the time, the print messages showed everything fine. But on every 10th attempt, or so, detected some “early signs” of errors from the print message. These occurred in cases where the camera reduced the clock speed to the SD card in the face of detected errors.

Fixing Corrupted SD Card and Dead Battery

Instead of allowing the camera to (optimistically) try to run the SD card at it’s maximum speed, and getting occasional data corruption as a result, I simply limit the SD card speed right from the start. This works because the SD card can easily keep up with the incoming video data even at the lower speed. There is probably a way to fix the firmware so that it could reliably work at higher SD card frequencies. such a fix may be necessary in the future for higher resolution video footage. Browning, please take care of this!

Note that as of this writing (2023-11-14) I do not have many hours of camera time to confirm that the problem is indeed solved. However, I was able to test this fix with my simple diagnostic program. Without the fix, the diagnostic program reliably encounters write errors. With the fix, it does not. So I’m confident that the fix will also prevent the much rarer write errors that have frustrated many of us when using the HP5.

You can download my firmware patches, which now includes this fix, from by GitHub site here.

Workarounds

If you’d rather not load a non-Browning firmware image onto your camera, there are some things you can do to reduce the chances that this bug gets you:

- When deploying the camera, after executing the “Delete All” menu item, take at least one photo/video. You can do this by pressing the “E” button while the camera is in the live-view mode. This creates the DCIM and xxxBTC subdirectories when the SD card is already stable in “menu mode”. It means the camera doesn’t have to create them on the fly on it’s very first trigger.

- Use a Slow SD card: This problem is related to cards with rated bandwidth’s in excess of 80 MB/s. Unfortunately, it’s difficult to find the newer, higher capacity cards in lower speed variants.

Sound Failure

The audio recorded on modern trail cameras should be very good. However, sometimes these trail cameras will lose sound completely, or develop a static or humming noise. Note that some brands of cameras, especially older cameras, may have design problems which limit sound fidelity. If a camera has poor sound “out of the box”, it may not be fixable. I added a new post covering replacement of the microphone in a Browning Elite HP5 camera.

Symptoms of Sound Failure

A camera that once had good sound, suddenly, or over time, does not. Sound may disappear completely, or it may become full of static, electronic humming, or popping.

Debugging Sound Failure

There are two likely causes of sound failure, both having to do with the small electret microphone typically mounted to the camera case. The microphone is connected to the printed circuit board with a pair of wires. Either the microphone itself has failed, or the wires have become disconnected from the circuit board. With the camera case open, a visual inspection will generally distinguish between these two cases. If the wires are connected to the circuit board, the problem is likely with the microphone.

Fixing Sound Failure

If the problem is disconnected wires, these can be tacked back on with are a small soldering iron and a delicate touch. The pads are very small, so high magnification of the work area is a must.

If the problem is with the microphone itself, then replacing the microphone with an equivalent is the solution. Here are some guidelines:

- Size: The microphone typically fits into a hole in the camera case. Prying away a little corner of the glue around the existing microphone to expose a thin plastic housing shell. Diameter of micrphone for recent Browning models is 6 mm.

- Microphone type: These are typically electret microphones (vs. MEMs microphones). These are inexpensive and have a simple, polarized, 2-wire interface.

- Dust/Waterproof: See https://en.wikipedia.org/wiki/IP_Code. A product rated IP57 is dust resistant (5) and is waterproof (7) to a depth of less than a meter. IP68 is completely dustproof (6) and waterproof (8) to a depth of more than a meter. IP57 should be enough (1 meter of water is a lot!), but you may want to look harder to find an IP67 (dust-proof, waterproof to 1 meter) or IP68 (dust proof, water proof to more than meter) device.

- Connection: Simplify your life by finding a microphone with red and black wires already attached. Leads should be at least 50 mm long.

For the Browning Elite BTC-8E-HP4 series (and likely other recent Browning models, at least back to the BTC-7 Advantage series), here are a couple of options. If you order any of these, make sure to find one with the small leads arlready attached to limit the amount of fine soldering you have to do.

| Microphone Part Number | Comments |

| CUI Devices CMC-6027-42L100 | Water Resistant (IP57) 6 mm electret microphone. Known to work on Browning Elite HP5 |

| Panasonic WM-61A | Known to work. The specs do not indicate how waterproof this unit is |

| Taidacent 4015 | Listed as IP67 Dustproof and waterproof to 1 meter |

| PUI Audio POW-1644L-LWC50-B-R | Listed as IP57 Dust resistance and waterproof to one meter |

Make sure to connect the microphone with the right polarity. The red, positive, wire should attach to the pad marked “+”, and black, negative, wire to the pad marked “-“.

I am indepted to blog subscriber Erik, who shared his experience replacing the microphone on his Browning Elite BTC-8E-HP4 with Panasonic WM-61A microphone in the comments section of Browning Spec Ops Elite HP5 Teardown and Inside the Browning Recon Force Elite HP4 (BTC-7E-HP4). Check out his videos showing his HP4 before and after replacing the microphone.

LCD Failure

Many cameras use a small LCD screen to display menu items and to preview photos and videos in the field. These LCD modules are of varying sizes and resolution, and are not generally interchangeable between manufacturers or within different model families. Based on experience, these LCD modules can fail over time in the harsh conditions of outdoor deployment.

Symptoms of LCD Failure

LCD failure is often clearly visible. Unlike “Video Artifacts” if an image is visible on the screen, it contains all the right elements, but the color may be off, or part of the screen may be dark or overly bright. The image may lack contrast. These aberrations exist in all menu modes, and not just the preview function.

Debugging LCD Failure

Debugging can be done by eye in most cases. To eliminate all doubt, owners of certain Browning trail cameras can use the hidden test mode to run the “Verification” test, which includes tests of the LCD. See: Hidden Test Mode in Browning Trail Cameras.

Fixing LCD Failure

In some cases, the LCD failure can be due to moisture damage to the flex cable connector at the socket on the PCB. Thus, any repair should start off by dassembling the camera to expose the LCD panel, and then carefully releasing the flex cable from the connector. Inspect for any visible signs of damage and clean if necessary. Re-insert the flex cable and try the camera again. If you are lucky, cleaning the connector fixed the problem. Video below shows removing LCD modules in Browning trail camera.

If the LCD problem persists, the LCD module itself needs to be replaced. Unfortunately, these LCD modules are typically only available to volume manufacturers (like Browning), and are hard to find at the retail level. Still, with the help of subscribers, I am working on a list of tested LCD modules for different cameras. See table below. Note that I cannot endorse or guarantee the products from the suppliers listed below, but they “worked” at least once.

| Camera Make/Model | LCD Module Part Number | Suppliers |

| Browning ReconForce and Spec Ops (BTC-{7,8}{A, E, E-HP4,E-HP5} | T20P96 LCD (240 x 320 2″) | AliExpress |

| Browning BTC-6HDPX | BL-T15P00V1 (240 x 320 1.5″) | AliExpress |

I am indebted to blog subscribers @Paolo and @damnfool034 for their help verifying vendors in this list.

Summary

Have you seen these failure modes? Others? Have you tried fixing these problems? Please comment below.

Disassembly Notes

Videos

Browning BTC-7A and 8A

I used a hooked dental tool to remove the “rubber stoppers” which keep water out of the 6 screw holes that hold on the back cover. Once these were out, I used a #1 Phillips head screwdriver to remove the screws.

The main PCB is likewise held in place 6 small screws. There are several sets of wires which connect the main PCB to: the battery pack; the front keypad; the microphone; and the IR LED array. It’s a little tight, but I found that I could get at most of the main PCB without removing any of these by careful manipulation of the board. The ribbon cable to front keypad is connected via a “flip-clamp” connector to PCBs on either end. The flip bar can released with a small flat screwdriver to release the cable and give a little more working flexibility. The other wires are all soldered to the main PCB.

The two screws for the heat sink fit directly into tapped holes in the heat sink itself. I found when tightening these screws that it was easy to strip them — an undesired outcome. It may be that the screw in question was already stripped when I got to it, which could have been part of the problem. These screws are tiny — smaller than 2 mm. I was able to insert a slightly larger screw (not sure exactly which size, possibly M 1.7) into the stripped hole and it self-tapped in the soft aluminum of the heat sink.

On reassembly, I sometimes found myself forgetting to re-install the little rubber stoppers into the screw holes in the case. This would have been a mistake, since these stoppers are part of the gasket system which keeps moisture out of the camera.

Lens Assembly and IR Filter

To access the lens assembly (e.g. for “Loss of Focus” fix), the IR filter must be removed. The IR filter is just held on with double sticky tape (!) to the face of the lens assembly. Prying it back and forth gently will loose the adhesive and allow removal. For reassembly, I scraped off the adhesive, applied another piece of double sided tape (making sure not to block the lens!) and stuck it back on.

References

- WildLabs camera trouble-shooting database: this conservation tech organization keeps a community spreadsheet where users can report camera failure modes. You may need to register to view this GoogleDoc.

- Seiko MS920T-FL27E Rechargeable coin Cell Battery with SMT pads: Available at multiple sources, including mouser.com.

- Browning Replacement Parts: PIR Lens

Very useful. Thanks.

Thanks, Peter. Hopefully you never need this information 🙂

Pingback:Trail Camera Noise: Part 1 - Clicks - Winterberry Wildlife

Thanks for such a informative article on how trail cameras fail, why they fail, and better yet, how to test for or fix some of these problems. Although I know nothing about those parts inside the camera, your article is so informative I might venture in and try open camera surgery the next time one is dead and out of warranty. Especially since I have several of the Browning cameras mentioned, and yes, they have had the failures you described. Your article really helped me understand how these cameras work. I have found all your articles/blogs related to trail cameras/camera trapping to be well written and includes beginner to expert level. Keep ’em coming!

I’m glad you found this post useful. If you decide venture into any of your out-of-warranty cameras, let us know how you made out. I have been (and will continue) to update this post with new information (e.g. new “Disassembly Notes”), so be sure to check before the surgery date 🙂

I haven’t had a PIR lens in hand and I can’t be sure from looking at the pictures. The black plastic is both a “cover” and a Fresnel lens built into that piece of plastic?

Therefore cutting out a scrap piece of plastic to the right shape would not work, as it has no Fresnel lens.

And while you can’t speak for all cameras, of the ones you have noticed other than Browning’s, would this be generally true as well? The plastic is the lens?

I guess I thought they were just pieces of plastic covering something underneath them – in the camera.

Yeap — the cover for the PIR sensor on all the cameras I’m aware of is also the Fresnel lens array — a critical element of the PIR sensor system. These lenses can sometime become brittle and break with age and UV damage, and sometimes they can be damaged by animal interactions. I know that Browning makes replacement lenses available on their website (though sometimes lenses are out of stock). I am working on a follow-on post on PIR sensors focusing on the structure of these lenses and the resulting “detection” zones. Stay tuned 🙂

Excellent-looking forward to learning about PIR sensors next, thanks!

Updated to include “Loss of Date/Time”

Pingback:Hidden Test Mode in Browning Trail Cameras - Winterberry Wildlife

Regarding the “Loss of Date/Time” in trail cameras. I in the past have also replaced the button battery. And like you have found only 3 volt rechargeable batteries in all the cameras I’ve repaired. Recently I had this failure on a Exodus Lift camera and I took a different approach to the repair.

This repair is always difficult especially if you are not well versed in micro soldering. The button battery on the Lift is located on the front side of the motherboard required complete removal of the motherboard along with the IR array, AA battery connections, ambient Light sensor and input switch assembly boards just to gain access to the battery.

To avoid all this disassembly work in the future I ordered a set of 10 BS-1220 coin battery holders online, total cost was $5.29 and two ML-1220 rechargeable batteries which cost $5.50 each. (Don’t be fooled and purchase CR-1220 batteries even if they are listed as rechargeable, they are not.) My total investment for repair was $6.03. While I can find surface mount button batteries for $2.50 each through specialty suppliers they do not include free shipping which can be as much as $10 per order.

Before I removed the button battery I confirmed the polarity of the connections. Also before removal the button battery showed 1.99vdc, after removal 2.3vdc. The fresh coin battery was 3.2vdc. Another upside to this repair is the ML-1220 is a 40mah battery while the button battery used on the OEM build is only 11mah. This nearly 4X increase in storage should improve the battery life.

I wired the the coin battery holder to the motherboard using #30 wire and glued the holder to the back side of the motherboard making it accessible by simply removing the back of the camera housing. I used a polyurethane adhesive, silicone RTV adhesives have an affinity for moisture which overtime might damage electrical circuits on the board.

I’ve just fielded the camera so I’ll post an update later to confirm or not the repair but as of the date it was fielded it appeared to be working correctly.

Thanks for the super-detailed comment! This sounds like a great solution to simplify the replacement of the real time clock battery in the future. These “hardwired” batteries often don’t seem to last as long as we’d expect. I look forward to hearing how your fix works!

Pingback:Avoiding False Triggers in Trail Cameras - Winterberry Wildlife

Updated to include two different failure modes for Date/Time. One in which date/time are reset to some factory default; and a separate, still mysterious failure, where camera “loses” time, on the order of ~hours per month.

Updated to include failure and replacement of PIR sensor lens

Great reading. Question I had my strike force out for a good four days. It took video up till the day before I retrieved it. When I opened it to shut down it wasn’t lit up. Upon checking the SD card their was no video of me taking camera down like usual. Popped on and off nothing checked battery try by popping in n out. It turned on fine and I got a video of me looking at camera. Is this something I need to worry about if I leave out for a longer period of time as I intend to ? The batteries were brand new energizer lithium ones. Just getting into trail cams and its fun but find myself flustered a lot! Thank you.

I think you discovered a corner case in the StrikeForce firmware!

I did an experiment with one of our StrikeForces where I replicated the sequence you describe. I set the camera up in (1-minute) video mode, let it count down to it’s sleep state; and then triggered it by waving my hand in front of PIR sensor. I then waited a varying amount of time before pushing the “mode” button.

I found that if I waited for more than about 5 seconds to hit the mode button, the camera did what I expected. It lit up the backlight, displayed the Browning splash screen, and showed the menu. I could review the abbreviated video of me “picking it up”.

However, if I went quickly for the mode button — I’m not sure what the number is exactly — but maybe a second or two, I saw exactly the behavior you describe when I hit the “mode” button — no backlight, no splash screen, no menu, even though I waited for a good long while. Interestingly, after waiting some time, the camera did respond to the mode key, but when it did, it was back in “trail camera” (still mode), having exited the “video” mode I had configured.

This leads me to suspect that when handling the “mode” button very early on in a video sequence, the firmware becomes confused (it may even “crash”). This causes some “backup” firmware to be executed, which resets the camera, hoping to avoid the situation again 🙂

At least that’s my theory.

I notice that as of October 7, 2021 , Browning has a firmware update for the BTC-5HD-26-CBP, which addresses a “power problem”. This is not quite the version of the Strikeforce I tested (which was a “plain” BTC-5HD). If it matches your camera, you should definitely do the firmware upgrade.

https://browningtrailcameras.zendesk.com/hc/en-us/articles/4408027055899-BTC-5HD-26-CBP-Power-Correction

But even if it’s not your model, I think you should be okay to use the camera, even with this “feature”. Everything about my experiments suggests the camera was working fine right up until time of retrieval. Now that you know about it, you can work around this firmware corner case.

For example, Janet and I have taken to turning the camera “off” with switch when we retrieve it, and waiting the full video length before turning it back on (vs. just hitting the “mode” button). This may not be necessary, but it seems to work for us.

We also run through all the settings to make sure they are set correctly before re-arming the camera. This is good practice, and necessary in the case you discovered.

Hope this helps. Good luck with your camera trapping. And thanks for commenting!

No pictures taken and after all tips applied. Can you recommend a pro to look at my trail camera. Stealth ZX36NG.

thanks,

Frank

Sorry to hear that your Stealth camera won’t take pictures. I am not aware of any independent professionals who repair these things. I suspect this is because with the cost of shipping, and the time to debug and repair (if a repair is even possible), it’s almost always less expensive just to get a new camera. Your best bet is likely to contact Stealth customer service (especially if its under warranty). Some e-tailers offer an extended warranty. E.g. if you bought it through TrailCamPro.com, you have a 2-year warranty with them.

If it’s out of warranty, I have a general curiosity about what goes into the different brands and models of trail cameras, and I’ve never opened up a Stealth model before. If you will cover shipping to and from, I will open it up, debug it, and do my best to fix. Best case, I’ll mail it back to you fixed in a week or so. But no guarantees. As I said, certain failures may not be (practically) fixable, and I may not be able to figure out what ails it. If either of these happens, I could either mail it back still broken, or dispose of it.

Let me know.

Hi Bob,

I have a couple of questions in regards to changing the coin cell battery in the Browning Recon Force/Spec Ops Advantage cameras. Are these batteries best attached to PCB board with a glue/adhesive or should they be soldered onto the board?

If not soldered, can you recommend a product?

Also I like the idea from Dan Potter on a battery holder that allows for easier battery changes and possible preferred easy accessibility as well as larger battery size. Please follow-up on this when you or Dan Potter have data to share on this for the above Browning cameras please.

Thank you

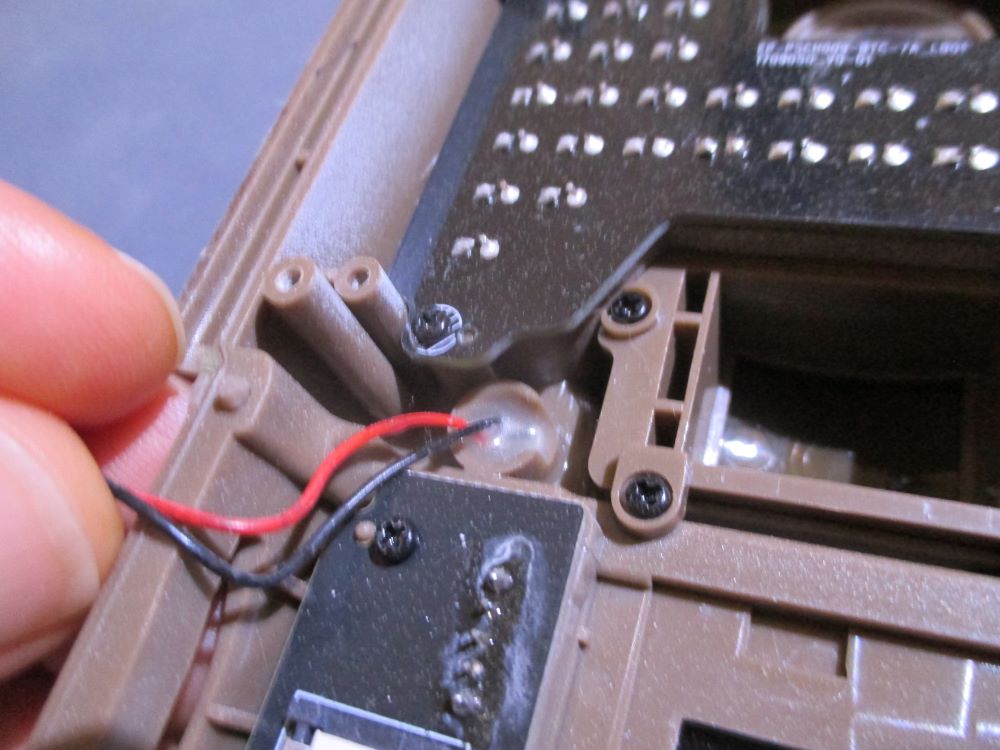

They are soldered to the board. See photo from “Stuck IR Filter” section in How (some) Trail Cameras Fail. The battery is up in the right hand corner of this board on the BTC-7A and 8A. They are definitely soldered down, but can still be replaced. I’ve never done it on the BTC-7A, so I haven’t looked at the battery type or form factor in detail. I’ll message DP and see if he has any update on the “remote battery” solution (which also requires removing the battery that’s soldered down to the board).

I’ve field that camera for about a month and it work perfectly. Pulled it and it sat in my office for a few weeks and was just put back into the field last week. Date and time seem to be holding well.

Excellent. Thanks for the update!

Thank you Bob (and Dan) but still have a question. If using the Seiko battery replacement that has the two prongs, are the prongs where you solder it to the board?

Should I also solder the round battery underside as well?

And you mention glue is used to hold the battery (and show it in the picture in the blog – as the “goo”) Is glue used just in the manufacturing of camera, but not necessary when replacing the battery? I’m asking because I’m not sure if I’m either going to short something out by soldering to many places, or invite moisture by using – or not using glue to surround battery as shown in the picture.

Thank you for clarification as I’m new to soldering.

Yes — the two tabs off the surface mount cell are the + and – pins. They need to be soldered to the PCB at the pads on the PCB. You’ll want to get some “solder braid” to help with the desoldering. See youtube demos for Super Wick (e.g. https://www.youtube.com/watch?v=_hrJ-rwxNRs) . I like the 0.050″ width for most SMT jobs.

You don’t need to worry about anything else (I don’t think). The goo/glue I found on an earlier Browning model was likely there to protect the battery during volume manufacturing. I don’t believe it’s necessary for hand replacement.

Looking at the BTC-7A, I see the markings:

ELNA 3.3V 0.2F jp

This is a 3.3Volt, 0.2 Farad Surface Mount ultracapacitor. An ultracapacitor provides energy storage in a slightly different way than batteries. I’m not sure that the charging circuit will support a battery-based replacement.

See: DSK-3R3E224U-E at https://www.digikey.com/en/products/detail/elna-america/DSK-3R3E224U-E/13693691

Unfortunately, my quick search of the internet shows that this particular style of SMT device (with the tabs very close to each other on one side) is now considered obsolete, replaced, apparently, by similar parts with leads on opposite sides of the coin cell. So my favorite electronics houses don’t have them in stock.

The newer style looks like this: DSK-3R3E204T614-E at https://www.digikey.com/en/products/detail/elna-america/DSK-3R3E204T614-E/13693693

Unfortunately, using the newer parts with older boards is problematical because the SMT pads aren’t in the right place.

But there’s always eBay:

https://www.ebay.com/itm/164811329362

10 of the older style, with the exact markings as on the BTC-7A, for $11.88. And you’ll have enough left to help your friends 🙂

-bob

Pingback:Inside the Browning Recon Force Elite HP4 (BTC-7E) - Winterberry Wildlife

Hi Bob,

I didn’t refresh my memory by watching your video first before I openned my BTC-8A.

I desoldered two wires that weren’t necessary AND lifted off a small conducting square.

Can this be fixed? I don’t know how to reattach square to board.

Also, this camera has “run on” but the heat sink is firm to board. Does heat sink come out easily to file in cutout around PIR?

PIR is flush mounted. Should I try lifting this up before I try cutout method?

I have pictures of small conducting square if needed.

Thank you

Will contact you via email shortly.

Per “run-on” in the 8A, I would try pushing the PIR sensor out first. The heat sink is attached by a thermal adhesive of some sort, and does not readily come off (I have never taken one off of a trail camera).

In any case, I would only try to tighten the heat sink onto the board, not modify it in any way. The issue, IMO, is not that it’s too close to the PIR sensor, it’s that it’s not working well enough getting the heat out of the CPU. Removing material from the sink could make this worse.

Pushing the PIR sensor out a mm or so is a little tricky. There are four leads that you have to free up. I used some solder braid (“superwick” 0.050″ from MG Chemicals). There are youtube videos on how this works. Basically, you press the copper braid onto the pad you want to remove the solder from with the hot tip of the soldering iron and wait for the solder to melt. Surface tension “wicks” the molten solder off of the circuit board and into the solder braid. In principle. In practice, it takes some patience.

Once all 4 pads are solder free, use the tip of a small screw driver to push them out about 1mm — not too far, since there has to be enough of the lead still in the hole to resolder it. Resolder it.

If this doesn’t work, best option is to increase the “photo delay” to 5 seconds (or more). Honestly, I would do this before removing the heat sink, but if you decide to remove heat sink:

I would remove the two screws holding it on, then try to “twist” (vs. “pull”) it off. Once off, I would use a soft tool (softer than aluminum — e.g. plastic) to remove the adhesive from the metal top of the processor and the bottom of the heat sink without putting any scratches in either surface. Maybe a dry cloth, as well. Your aim is to create two smooth, flat surfaces. Then, apply a thin layer of new-thermal adhesive (available on amazon), and tighten the heat sink down with the screws. One of the reasons I’m wary of these steps is that the manufacturer may use a special fixture to push the heat sink onto the top of the processor. Too much pressure and you could break the processor (fatal to the project); too little and you may be worse off than when you started.

Pingback:Browning Spec Ops Elite HP5 Teardown - Winterberry Wildlife

Hi, I am having apparently unique problems with my trail cam. I have a GardePro A3 trail cam that worked pretty well when I first started using it but gradually developed sound issues and triggering problems. But the weirdness is that the sound problems are only during night vision recording. Daylight recording has audio that sounds fine.

The triggering issue was that I was noticing that animals I saw with my own eyes were not being recorded. The camera just didn’t trigger to record at all. I started noticing that it was always when my dog was barking out the back door at the animal in the yard. It was like the sound of her barking furiously would interfere with or disable the motion sensor somehow. This morning I realized that after 3 months of using this camera every night, there should have been dozens of videos where you can hear my dog barking in the background. But there is not a single one! How is this possible? (The screen door is about 8 or so feet from where I have the camera set up on the patio.) How could a loud noise cause the camera to fail to trigger?

Sorry to hear that your’re having trouble with your camera. I have some ideas, but best to inform them with a little more information. A few quick questions for you:

1. Has there been any evidence of moisture in the camera? Possibly condensation on the inside of the lens cover, on the SD card, or on the batteries after a heavy rain?

2. What’s the nature of the sound failure at night? No sound at all? Or sound with electronic noise in the background? Or something else?

3. How is the camera mounted relative to the motion of animals? Do the animals typically move horizontally across the frame, or more towards the camera? (I know this is a tricky question, given that the camera isn’t taking pictiures 🙁 ) How far off the ground is the camera?

Any thoughts on a camera ( BTC-6HDPX Dark Ops HD Pro X ) that underexposes pic’s right out of the box? Pictures are color-correct but a bit blurred compared to my BTC-5HD’s, but they seem dark and detail in shaded areas is gone.

I assume the dynamic balance is internal to the camera, but if not does the photocell have any input to the camera settings other than IR on/off?

By the way thanks so much for posting your cam fix findings, I searched for years for such detailed info for the Bushnell Trophy Cams, and finally gave up on fixing them and moved to Browning.

No problem. I figure since I’m running across these problems anyway, might as well post them for the rest of the world.

Re underexposure on the BTC-6HDPX right out of the box. I’ve not used any of this type of camera. Do you have other instances of the same camera that don’t have this problem? Maybe “they all do that”? :/ Does it do it all the time? In photos and videos? Daylight and night images?

The blurriness could be a problem with the lens (see “Loss of focus” in this post), but let’s assume its part of an under exposure problem. To the best of my knowledge, the auto-exposure uses data from the image sensor to dynamically adjust exposure. As you suspect, the photo cell is only used to inform whether image is daylight or night time.